Conveyor belt for high temperature materials

Conveyor belt for high temperature materials refers to a conveyor belt system specially used for conveying high-temperature block, granular or powdery materials above 80°C. It has high temperature resistance, ablation resistance, heat aging resistance and tear resistance, and is widely used in hot material conveying scenarios in cement, metallurgy, casting, power and other industries.

Product Introduction

Conveyor belt for high temperature materials is an industrial transmission component designed specifically for conveying materials with high temperature characteristics. Its core function is to stably convey materials in a high temperature environment while ensuring that its own structure is not damaged and its performance is not significantly reduced. Based on high temperature resistant materials, special industrial equipment designed in combination with material temperature, physical properties and transmission requirements, through structural optimization, balances stability, wear resistance and functionality in high temperature environments, and is widely used in temperature-sensitive heavy industrial scenarios.

Applicable materials for conveyor belt for high temperature materials

High temperature materials refer to granular or powdery materials with continuous or instantaneous high temperature (generally ≥80°C, commonly up to 200~800°C) during the conveying process, mainly from metallurgy, building materials, chemical industry and other thermal processing processes.

|

Material name |

common temperature range |

particle size (mesh) |

characteristics |

|

Clinker (such as cement clinker) |

120~200°C |

10~100 mesh |

block + dust mixed, heat concentrated |

|

Limestone powder |

80~150°C |

100~300 mesh |

powder, easy to raise dust, accompanied by corrosiveness |

|

Slag |

200~600°C |

20~80 mesh |

block/granular, high hardness, strong impact |

|

Metal particles/cutting chips |

100~500°C |

variable |

strong thermal conductivity, easy to scratch conveyor belt for high temperature materials |

Conveyor belt for high temperature materials video

The essential difference between conveyor belt for high temperature materials and ordinary conveyor belts

|

Comparison dimension |

Conveyor belt for high temperature materials |

ordinary conveyor belts |

|

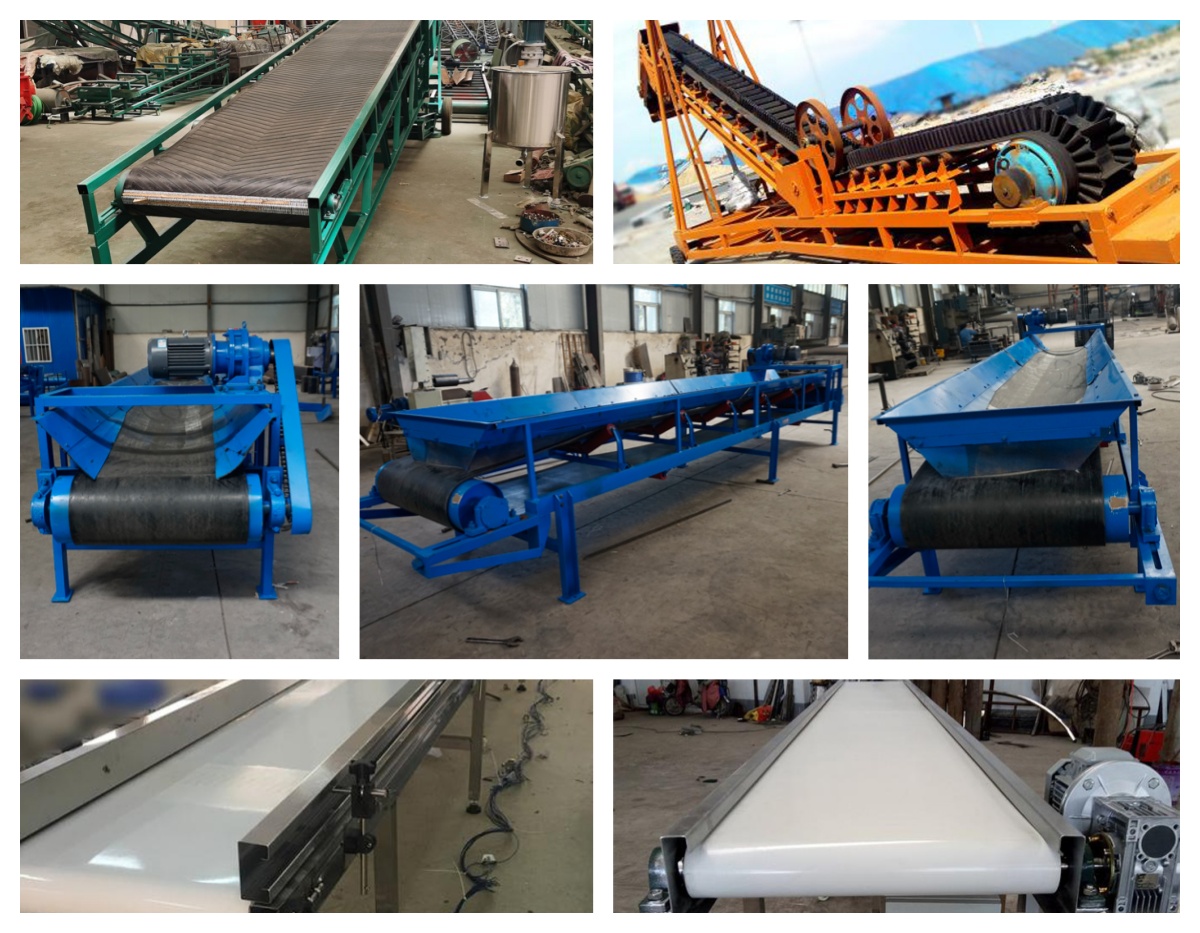

Images |

|

|

|

Core materials |

metal mesh, ceramic fiber, silicone rubber, etc. |

rubber, polyester fiber, cotton canvas, etc. |

|

Temperature range |

150℃~1200℃ |

normal temperature~80℃ (some rubber belts are resistant to 120℃) |

|

Structural design |

multi-layer insulation, thermal shock resistance, high-strength skeleton |

single or double-layer adhesive structure |

|

Application scenarios |

high temperature working conditions such as metallurgy, ceramics, glass, cement |

normal temperature material transportation in logistics, food, and mining |

Challenges faced by conveyor belt for high temperature materials

Material expansion and deformation: Increased temperature causes traditional materials to expand, thereby reducing the stability of the conveyor belt.

Reduced strength: High temperature weakens mechanical properties and increases the risk of breakage and damage.

Reduced wear resistance: Materials conveyed under high temperature conditions may cause additional wear on the conveyor belt.

Chemical reaction: High temperature environment may cause chemical reactions between the conveyor belt material and the transported material, affecting its service life.

To solve these problems, it is crucial to select a conveyor belt for high temperature materials with excellent heat resistance.

Selection of Conveyor belt for high temperature materials

Different high temperature environments require different types of conveyor belt materials. The following are some common Conveyor belt for high temperature materials materials and their characteristics:

1. Polytetrafluoroethylene (PTFE) Conveyor belt for high temperature materials

Temperature range: -200°C to +260°C

Features: low friction coefficient, reduced wear; high chemical stability, acid and alkali corrosion resistance; excellent electrical insulation, suitable for the electronics industry

Application areas: food processing, semiconductor manufacturing, chemical industry

2. Polyimide (PI) Conveyor belt for high temperature materials

Temperature range: up to 300°C+

Features: excellent mechanical properties, tensile and tear resistance; strong corrosion resistance, suitable for harsh environments; maintain stability at high temperatures

Application areas: oil refining, metal processing, aerospace

3. Metal Conveyor belt for high temperature materials (stainless steel/nickel alloy/titanium alloy)

Temperature range: up to 1000°C+

Features: Suitable for extreme high temperature environments; high strength and rigidity, suitable for heavy-duty material transportation; corrosion-resistant, suitable for high-temperature chemical environments

Application areas: steel smelting, coal processing, glass manufacturing

4. Silicone rubber conveyor belt for high temperature materials

Temperature range: -60°C to +200°C

Features: good elasticity and flexibility; suitable for conveyor belt applications with complex shapes; chemical corrosion resistance, suitable for certain special environments

Application areas: food processing, pharmaceutical industry, glass manufacturing

Conveyor belt for high temperature materials material comparison

The following table compares different materials based on heat resistance, characteristics and applications:

|

Material |

Maximum heat resistance |

Main features |

Typical applications |

|

PTFE (polytetrafluoroethylene) |

260°C |

Low friction, chemical resistance |

Electronics, semiconductors, food transportation |

|

PI (polyimide) |

Above 300°C |

High strength, heat resistance |

Refining, metal processing |

|

Metal conveyor belt (stainless steel) |

Above 1000°C |

Extremely high heat resistance |

Coal, metallurgy, glass manufacturing |

|

Silicone rubber |

200°C |

flexible, high temperature resistant |

Glass production, food processing |

Mesh number recommendation for conveyor belt for high temperature materials

The mesh number refers to the mesh density of the filter on the surface of the conveyor belt, the unit is "mesh/inch" (number of holes/25.4mm), which is used to control the passability or retention of material particles.

Application scenario:

Low mesh number (coarse screening): such as 20~60 mesh, suitable for conveying large particles of high temperature materials (such as blast furnace slag, coke), allowing fine dust to pass through to avoid blockage.

High mesh number (fine screening): such as 100~300 mesh, used to filter high temperature liquids or fine particles (such as glass molten liquid impurity removal, metallurgical slag liquid separation), high temperature resistance and screening accuracy must be taken into account.

Key technical parameters of high-temperature material conveyor belt

Conveyor belt for high temperature materials is a special conveying equipment designed for continuous or intermittent contact with high-temperature materials. It solves the problems of belt aging, deformation, and strength reduction caused by high temperature through heat-resistant materials, cooling technology, and heat-fatigue-resistant structure.

|

Parameters |

High-temperature belt requirements |

Ordinary conveyor belt comparison |

|

Temperature resistance level |

T1 (100℃)~T4 (400℃) or customized higher |

Ordinary belt (-10~80℃) |

|

Thermal elongation |

≤2% (under 200℃) |

Ordinary rubber>5% |

|

Cover thickness |

Upper cover 6-15mm (wear resistance + heat insulation) |

Ordinary belt 3-5mm |

|

Cooling method |

Air-cooled/water-cooled roller, spray system |

No cooling design |

|

Life (high temperature) |

6 months~2 years (depending on working conditions) |

Ordinary belt is only 1-3 months at 200℃ |

According to the conveying temperature, pipeline belts are divided into different grades:

T1: Temperature resistance ≤120°C (such as ordinary hot powder).

T2: Temperature resistance ≤ 150°C (such as cooked cement).

T3: Temperature resistance ≤ 180°C (such as hot coal slag).

T4: Temperature resistance ≤ 400°C (such as steamed ore).

Higher levels (such as 600°C+) require special materials (such as steel mesh belts or ceramic composite materials).

Application of Conveyor belt for high temperature materials

Metallurgical industry: In the evaporation workshop of the steel plant, the evaporation ore (temperature 500-800°C, mesh number <60, diameter 10-50 mm) is output from the evaporation machine and needs to be quickly piped to the cooler or blast furnace raw material bin. The Conveyor belt for high temperature materials is responsible for conveying the evaporation ore from the tail of the evaporation machine to the next pipeline.

Cement industry: The clinker temperature production line of the factory, high-temperature clinker (200-400°C, mesh number 60-150, diameter 0.1-0.25 mm) is output from the rotary kiln and needs to be conveyed to the clinker cooler or storage. The pipeline belt conveys the clinker cement from the tail kiln to the conveying cooling system. (1-1.5 m wide, 0.5-1.5 m/s in speed)

Chemical industry: In the catalyst production line of a chemical plant, high-temperature catalyst (temperature 200-500°C, mesh size 200-400, particle size <0.074 mm) is output from the reactor and needs to be piped to a cooling device or packaging line. The pipe belt transports the catalyst from the bottom of the reactor to the screening or cooling equipment. (0.6-1 m wide, 0.2-0.5 m/s in speed)

Glass and ceramic industry: In a glass manufacturing plant, hot glass raw materials (such as silica sand, limestone, temperature 300-600°C, mesh size 100-200) are output from the furnace and need to be piped to the molding machine or cooling area. The pipe belt transports the raw materials from the melt discharge port to the next conveying pipeline. (width 0.8-1.2m, speed 0.3-0.8m/s)

Hot fly ash industry: In coal-fired plants, hot fly ash (temperature 150-250°C, mesh size 150-300, diameter 0.05-0.1mm) is output from the bottom of the boiler or the electric precipitator and needs to be piped to the ash storage or recycling system. Conveyor belt for high temperature materials transfers fly ash from the ash hopper to storage or processing equipment.

Why choose Dahan Machinery?

The reasons for choosing Dahan Machinery can be comprehensively analyzed from multiple dimensions such as its technical strength, product quality, service system, and market reputation.

Strength guarantee: more than 20 years of experience in conveying equipment manufacturing, focusing on the field of bulk material conveying, products covering the whole country, and exported to Southeast Asia, Africa, the Middle East, South America and other regions.

Technology leadership: provide one-to-one customized services, accurately match the conveying solution according to the material characteristics (temperature, etc.), have a variety of conveying structure types, and support non-standard customization.

Reliable products: The conveyor belt material is wear-resistant, tear-resistant, and anti-aging, with a long service life, modular structural design, easy installation, and simple maintenance.

Service in place: one-stop supply of complete machine + accessories, timely delivery, installation and commissioning, operation training, maintenance support, remote technical guidance, experienced after-sales team, national service outlets, 24-hour response.

If you need to know more about the specific product models or cases of Dahan Machinery, you can visit its official website (https://www.auger-conveyor.com) or contact its sales team for detailed quotations and technical support.