Conveyor belt for powder materials

Conveyor belt for powder materials is a continuous conveying equipment designed to adapt to the characteristics of powders. Through sealing structure, dust prevention technology, anti-sticking materials, etc., it can realize efficient, clean and safe transmission of powder materials. Its core features are anti-dust, anti-adhesion, anti-static and adaptive particle size (fine powder anti-leakage, coarse powder anti-slip).

Product Introduction

Conveyor belt for powder materials is a continuous conveying equipment designed for powder materials with small particle size, easy flow or easy adhesion. The powder is transferred from the feed end to the discharge end through the movement of the ring conveyor belt. Its core function is to convey powder materials stably, efficiently and with low loss, while meeting special requirements such as dust prevention, anti-adhesion and corrosion resistance. It is specially designed for conveying fine powder, micro powder and other high-flowability and high-dust materials. It is widely used in bulk material conveying systems with high environmental requirements in industries such as building materials, chemicals, and electric power.

Common powdered materials

Powdered materials refer to materials with very small particle sizes and close to powder state. They are often in bulk form and are widely used in building materials, chemicals, electricity, grain and other industries. Common powdered materials include cement powder, coal powder, flour, lime powder, talcum powder, carbon black, mineral powder, fly ash, etc.

Summary of characteristics:

Powdered materials refer to loose solid materials composed of fine particles, and their particle size is usually less than 1mm. They have the following significant characteristics:

Fine particle size: The particle size is usually between 0.001 mm and 1 mm, sometimes as fine as micron level (μm)

Easy to raise dust: It is very easy to drift with the air flow during transportation, causing dust pollution and material loss

Strong accumulation: The friction between particles is large, the fluidity is poor, and it is easy to bridge and block materials

Hygroscopicity/viscosity: Some powders such as cement, lime, flour, etc. have certain hygroscopicity, which may cause adhesion and blockage

Light specific gravity: Many powder materials have a lower density than block and granular materials, but have a large specific surface area and are prone to static electricity accumulation

Video of conveyor belt for powder materials

What is the working principle of conveyor belt for powder materials?

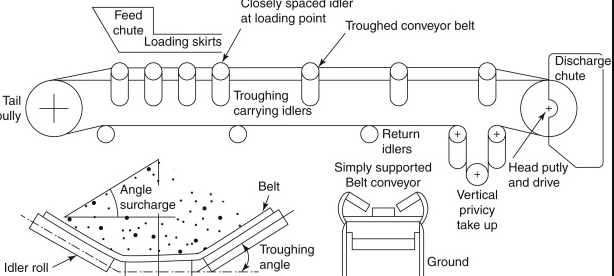

Conveyor belt for powder materials works together through the core components such as the conveyor belt body, drive device, tensioning device, roller system, etc., combined with special designs such as dust prevention, leakage prevention, and anti-static to achieve efficient and stable transportation of powdered materials.

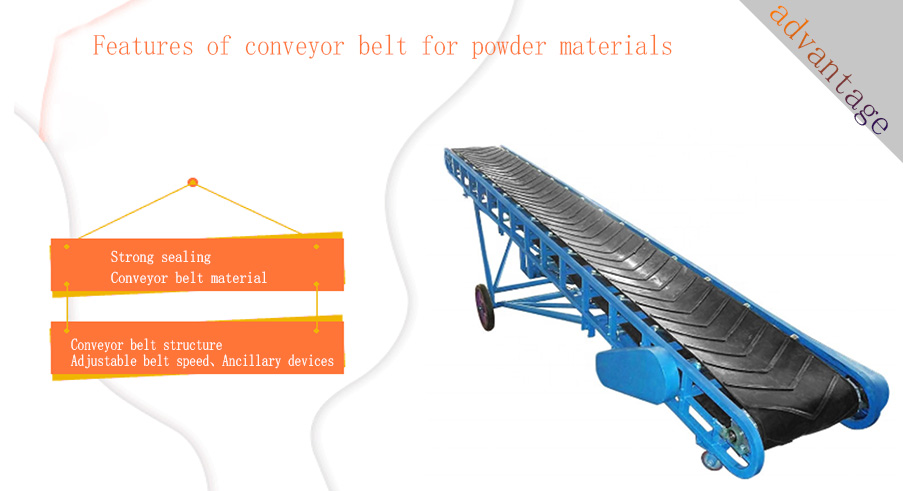

Features of conveyor belt for powder materials

Strong sealing: prevent dust flying and material leakage, optional cover, closed cover, tubular conveyor belt structure

Conveyor belt material: use wear-resistant, anti-stick, anti-static, flame-retardant and other performance materials to prevent powder from sticking or slipping

Conveyor belt structure: recommended corrugated sidewall belt, skirt belt, closed conveyor belt, pipe belt machine, etc., can adapt to inclined or turning routes

Adjustable belt speed: controlled at 0.8~1.6 m/s, the powder conveying speed should not be too fast to prevent dust from being raised

Ancillary devices: equipped with sweepers, material guide skirts, dust collectors, tensioning mechanisms, etc. to ensure stable operation of the system

Technical parameters of conveyor belt for powder materials

|

Parameters |

Typical range/requirements |

Description |

|

Belt width (mm) |

500-2000 |

Narrow for fine powder (to prevent dust), wide for coarse powder (to increase transportation capacity) |

|

Belt speed (m/s) |

0.5-2.5 |

Low value for fine powder (<1m/s to prevent drifting), high speed for coarse powder |

|

Sealing level |

IP65 (dustproof and waterproof) |

IP69K (high pressure washing) required for chemical/food industries |

|

Antistatic performance |

Surface resistance <10⁶Ω (ISO 284) |

Combustible dust (such as aluminum powder) needs to be <10⁴Ω |

|

Temperature resistance (℃) |

-30~120 (conventional)/ Up to 800 (heat-resistant zone) |

High-temperature powders (such as cement clinker) require special heat-resistant layers |

Recommended mesh number for conveyor belt for powder materials

Mesh number is a common unit for measuring powder particle size, which refers to the number of holes per inch on the screen. The larger the mesh number, the finer the particles. As shown in the following table:

|

Mesh size (mesh) |

Corresponding particle size range (mm) |

Examples of common powder materials |

|

Below 60 mesh |

> 0.25 mm |

Coarse powder, sand powder, feed powder |

|

80~200 mesh |

0.074 ~ 0.18 mm |

Lime powder, coal powder, cement, talcum powder |

|

200~325 mesh |

0.044 ~ 0.074 mm |

Flour, ceramic powder, calcium carbonate, carbon black |

|

Above 325 mesh |

< 0.044 mm |

Ultrafine powder (such as high-purity quartz powder, nano-grade) |

Application of conveyor belt for powder materials

Food processing industry: Conveying of food-grade powders such as flour and starch, such as wheat flour storage and transportation in flour mills, milk powder batching lines in dairy factories, and baking raw material production lines. Use food-grade PU or silicone powder material conveyor belts, which have a smooth and easy-to-clean surface to prevent material residues from breeding bacteria.

The transportation of pharmaceutical powders (such as APIs) and chemical raw materials (such as titanium dioxide) is common in pharmaceutical preparation workshops and chemical raw material storage logistics lines. When conveying low-fluidity powders, grooved rollers are used to support the U-shaped cross-section, and the skirt prevents the powder from leaking sideways.

Mineral and metallurgical industry: The transportation of industrial bulk powders such as mineral powder, fly ash, and coal powder is common in mine beneficiation plants and ash storage bins in thermal power plants. Wear-resistant rubber conveyor belts with a thickness of 8~12mm are used, and diamond patterns are added to the surface to enhance friction and prevent wear of mineral powder particles.

Building materials industry: The transportation of cement, gypsum powder, putty powder, and ceramic raw materials is common in cement plant finished product warehouses, building materials processing plant batching workshops, and ceramic plant glaze lines. PVC powder material conveyor belts are selected, and the surface is roughened to prevent gypsum powder from adhering.

Supplier of conveyor belt for powder materials

The core value of conveyor belts for powder materials lies in overcoming the special conveying difficulties of powder materials through technical design, such as anti-static design, large angle structure, wear-resistant materials, etc., to ensure efficient, safe, and low-loss conveying experience. When choosing, you need to pay attention to its dustproof, anti-blocking, and material adaptability to ensure long-term and stable operation of the equipment.

If you need further assistance, such as obtaining specific product specifications, quotes, or technical support, please let me know your specific needs and I will be happy to help you.