Food grade conveyor belts for meat products

Food grade conveyor belts for meat products are a kind of belt conveying equipment made of food grade materials and stainless steel or other sanitary structural materials. They are specially used in the production line of meat products to ensure food safety, processing efficiency and equipment durability.

What is a food grade conveyor belt for meat products?

Food grade conveyor belts for meat products are conveying equipment designed for the meat processing industry. They are used to achieve continuous and stable transportation of products in various links such as meat handling, processing and packaging. The core difference between it and ordinary industrial conveyors is that it meets food contact safety standards, is easy to clean, corrosion-resistant, and has a hygienic structure. It is suitable for conveying various types of meat products such as fresh meat, cooked meat, frozen meat, and pickled meat.

Meat products commonly conveyed by food grade conveyors

Fresh raw meat: such as unprocessed or preliminarily cut meat pieces such as pork front leg meat, beef tendon meat, chicken breast, and lamb chops.

Frozen meat: such as frozen chicken, frozen beef, frozen pork chops, etc., which are hard, heavy, and easy to frost on the surface.

Marinated meat products: such as marinated chicken legs, marinated steaks, seasoned pork slices, etc., which contain seasoning liquid, are easy to drip, and are slightly sticky.

Cooked meat: such as sausages, ham, cooked chicken nuggets, meatballs, etc., which are soft in texture, high in oil content, and have high requirements for hygiene level.

Cut meat, sliced meat: such as beef slices, chicken shreds, pork cubes, etc., which are irregular in shape, light in unit weight, and have a large conveying volume.

Classification of food grade belt conveyors

|

Classification type |

Picture |

Applicable meat products |

Description |

Application scenarios |

|

Horizontal conveyor |

|

Raw meat, cooked meat |

Commonly used for short-distance transportation, simple structure, suitable for packaging, picking, sorting and other processes |

Primary processing, packaging line |

|

Climbing conveyor |

|

Meat blocks, semi-finished products |

With a certain angle of inclination, suitable for conveying from the discharge port to a high place, such as packaging machines, hoppers, etc. |

Loading and unloading, cross-floor transportation |

|

Curving conveyor |

|

Meat products, packaged products |

Can achieve 90° or 180° conveying direction conversion |

Commonly used for complex layouts in workshops |

|

Modular assembly line conveyor |

|

Various meats |

Multi-section connection structure, can link multiple workstations |

Complex production line layouts such as cooked food assembly lines, weighing and packaging lines |

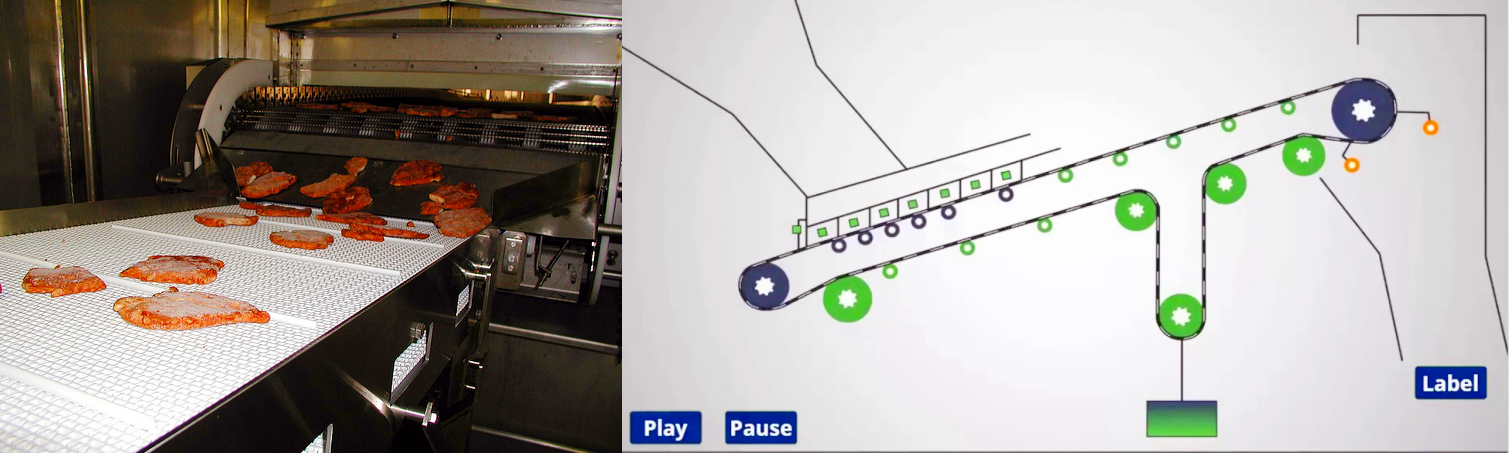

Working principle of stainless steel food grade conveyor belts for meat products

Stainless steelfood grade conveyors belts for meat products are driven by electric motors, which transmit power to the drive shaft through a reducer. The drive shaft drives the conveyor belt (usually made of food grade stainless steel or other suitable materials) to move along the conveyor track. Meat products or other materials are placed on the conveyor belt, and as the belt moves, the materials are transported to the predetermined location or the next process. The conveyor is equipped with guide rails or edges to ensure that the material does not fall during the conveying process and remains stable. This design ensures efficient and safe material transportation and is suitable for various food processing occasions.

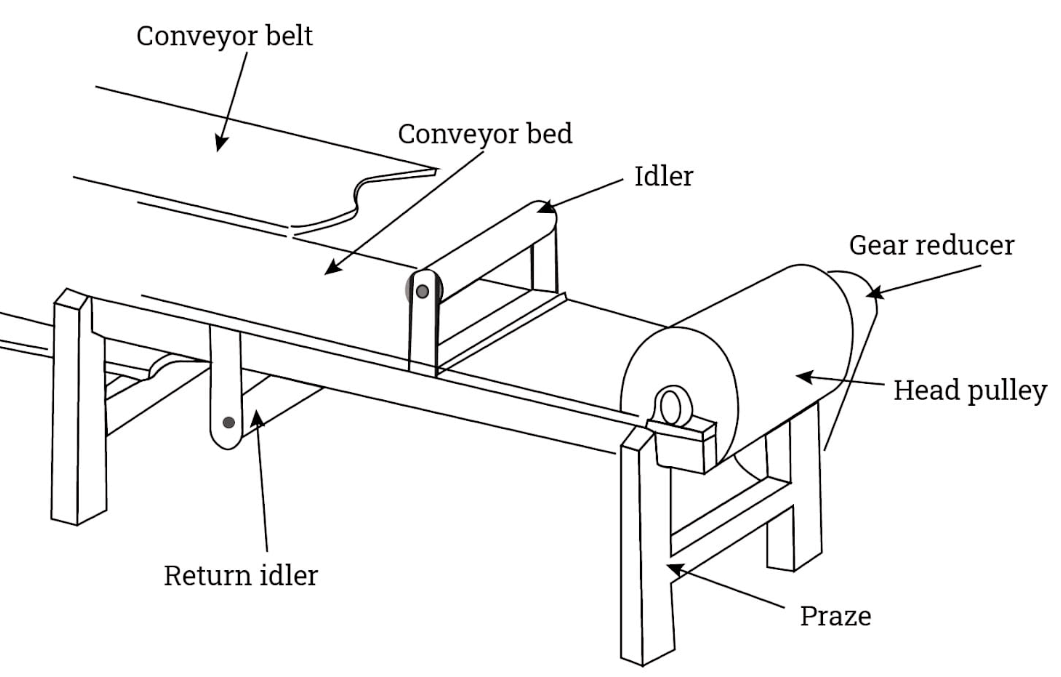

Structural composition of stainless steel food grade conveyor

Stainless steel food grade conveyors are essential equipment in the food processing industry, designed to safely and efficiently transport food to various processing and packaging stages. These conveyors are manufactured with high-quality stainless steel components that meet strict hygiene and safety standards. The main components of stainless steel conveyors include:

Conveyor frame: The frame is the backbone of the conveying system and provides structural support for all other components. It is usually made of stainless steel tubes or metal plates with a smooth polished surface that is easy to clean and disinfect.

Conveyor belt: The conveyor belt is the surface that transports food. Food-grade conveyor belts are made of non-toxic, non-absorbent, and antibacterial materials, such as stainless steel mesh, plastic modular conveyor belts, or special materials such as silicone.

Drive system: The drive system consists of a motor, gearbox, and sprocket to power the conveyor belt. The motor and gearbox are usually enclosed in a stainless steel housing to prevent moisture and contamination; the sprocket is made of stainless steel or food grade plastic for easy cleaning.

Brackets and pulleys: Brackets (such as legs and brackets) are used to fix the conveyor frame and ensure it is properly aligned. Pulleys guide and support the conveyor belt and are equipped with food grade bearings to ensure smooth rotation of the conveyor belt. Brackets and pulleys are made of stainless steel, which is durable and easy to clean.

Accessories: Food-grade conveyors may include a variety of accessories, depending on the specific application, such as guides, dividers or side walls to fix the product in place, or cleaning systems (such as scrapers or brushes) to remove debris from the belt.

Main structural features

Material safety and hygiene: Food-grade PVC, PU or silicone conveyor belts are used, which meet FDA or EU food contact material standards. Oil-resistant, waterproof, easy to clean, the surface can be smooth or textured to prevent product sliding. For scenes with blood or grease, PU belts are preferred, which have better corrosion resistance and cleaning resistance.

Good surface properties: The conveyor belt surface is smooth and flat, with a dead angle design, easy to clean and disinfect, which can prevent bacterial growth and food residue retention, and reduce the risk of cross contamination. The frame and bracket are usually made of 304 stainless steel, which is corrosion-resistant and easy to wash. The welding parts are polished smooth to avoid meat scraps or bacterial growth.

Strong corrosion resistance: Various cleaners and disinfectants are used in the meat processing process. Food-grade belt conveyors have good chemical resistance, can resist the erosion of chemicals, and maintain stable performance. Meat products are heavy, and the conveyor belt needs to bear a heavier load. Food-grade belt conveyors have high strength and wear resistance.

Wide temperature range: Meat processing involves freezing and heating processes. The conveyor belt of this conveyor can withstand temperature changes, does not deform in high temperature environments, and does not become brittle in low temperature environments, meeting the different temperature requirements of meat processing.

Strong customization capabilities: The width, length, and height can be customized according to different meat products (such as chicken, beef, pork), and baffles, side guides, turning devices, lifting platforms, etc. can be added.

Technical specifications of food grade conveyor belts for meat products

|

Parameter classification |

Parameter items |

Technical indicators/options |

Remarks |

|

Basic material |

Material type |

PU / PVC / Silicone / PE / Stainless steel food grade conveyor belt |

PU and silicone food grade conveyor belts are preferred |

|

Basic material |

Color |

White (standard), blue, green (anti-fouling and visible) |

White is the most commonly used, meeting the visual requirements of food hygiene |

|

Physical properties |

Thickness |

0.5~10 mm (PU/PVC commonly used 1~3mm, stainless steel mesh belt 1~5mm) |

Select according to the load, thick belts are wear-resistant but have reduced flexibility |

|

Physical properties |

Tensile strength |

5~50 N/mm² (PU is the highest) |

For high strength requirements, choose steel wire reinforced type |

|

Physical properties |

Temperature range |

-40°C~250°C (Silicone is the widest, PU is usually -20°C~80°C) |

For ultra-low temperature, choose PE, for high temperature, choose silicone or stainless steel |

|

Physical properties |

Surface treatment |

Glossy/patterned/anti-stick coating (Teflon)/antibacterial coating |

Anti-stick is used for dough and candy, antibacterial is used for fresh food |

What can food grade belt conveyors be used for meat products?

Food grade conveyor belts for meat products can be used to transport whole livestock to the cutting area after slaughter, to transport different parts of meat during the cutting process, and to transport the cut meat to the packaging stage. In the pickling pool or pickling workshop, meat products are transported from the pickling pool to the next process, or transferred between different pickling areas. For cooked and processed cooked meat products, such as ham, sausage, and stewed food, food grade belt conveyors can be used to transport products for subsequent processing such as cooling and packaging. During the freezing and refrigeration of meat products, it can be used to transport meat to designated locations in freezers or cold storages, as well as to carry and sort goods in the warehouse.

Precautions for selecting food grade belt conveyors for meat products

Whether the conveyed meat products are fresh or cooked, whether there are a lot of grease, blood, etc., determines the belt type and structural material.

Whether weighing, metal inspection, rejection, sorting, etc. are required during the conveying process determines whether integrated equipment is configured.

Whether the working environment is low temperature (such as cold storage), humid, corrosive cleaning agents, etc., determines the equipment sealing and protection level.

Food grade belt conveyors are used in meat products in various scenarios

Slaughterhouse: used for the transportation of raw carcasses or cut meats of pigs, cattle, chickens, etc.

Deep processing workshop: transports cooked meat products after pickling, steaming, smoking and roasting.

Packaging workshop: connects weighing machines, metal detectors, labeling machines and other equipment to complete the final packaging.