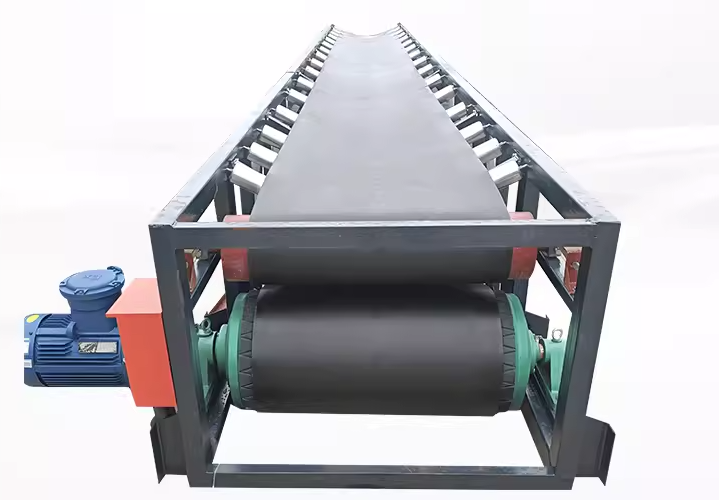

Heavy duty belt conveyor

Heavy duty belt conveyor is a continuous conveying equipment designed for conveying bulk materials, high load and long distance operations, suitable for heavy load and high strength material conveying.

Belt width: 500mm-2400mm

Conveying length: 10m-2000m

Conveying capacity: 50t/h-5000t/h

Belt material: ordinary rubber belt, tropical belt, acid and alkali resistant belt, steel cord belt, etc.

Drive mode: electric roller, reducer + motor drive

Application: widely used in heavy industries such as mining, metallurgy, electricity, ports, cement, building materials, etc.

What is a heavy duty belt conveyor?

Heavy duty belt conveyor is a conveying equipment with large conveying capacity, stronger structure and adaptability to harsh working conditions compared to light conveyors. It is suitable for conveying materials with high bulk density (such as less than 1.67 tons/cubic meter), large or heavy materials, such as coal, ore, sand and gravel, cement, etc., and is suitable for horizontal or inclined conveying systems.

What is the main function of a heavy duty belt conveyor?

The main function of a heavy duty belt conveyor is to efficiently and continuously convey large or heavy bulk materials or finished items. Heavy duty belt conveyors can continuously convey large amounts of materials and are suitable for bulk, block, granular or mixed materials such as coal, ore, limestone, cement clinker, sand and gravel. The conveying capacity can generally reach hundreds of tons or even thousands of tons per hour, meeting the needs of high-intensity production lines.

Compared with other conveying equipment, heavy duty belt conveyors can handle larger amounts of materials and achieve longer conveying distances, which is particularly important in scenarios such as mines, ports, and large factories. It can achieve 24-hour uninterrupted continuous conveying, greatly improving production efficiency and automation levels. The sturdy structure and diverse belt materials enable it to adapt to harsh working environments, such as dusty, humid, abrasive or temperature-changing places.

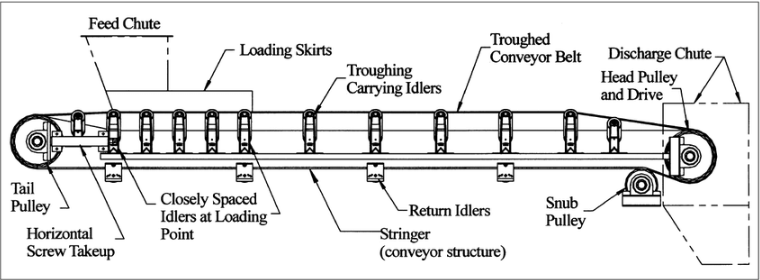

Structural composition of heavy duty belt conveyors

Conveyor belt: As the central component, it is usually made of rubber, PVC or other composite materials, has good wear resistance and tensile strength, and is a key part of carrying and conveying materials.

Driving device: The conveyor belt is driven by the motor and the reducer to provide power for the conveyor, so that the conveyor belt can run continuously and stably.

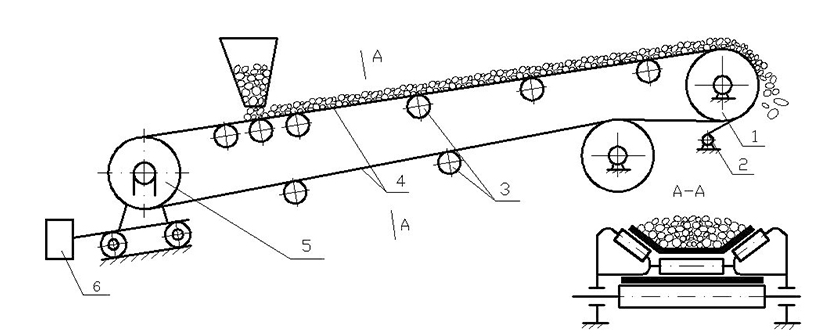

Roller: Supports the conveyor belt and reduces friction resistance to ensure the smoothness of the conveying process. According to different positions and functions, it can be divided into load-bearing rollers, return rollers, etc.

Tensioning device: Used to adjust the tightness of the conveyor belt to prevent slipping or deviation, and ensure that the conveyor belt has appropriate tension to ensure the normal operation of the conveyor.

Frame: It is the supporting structure of the entire conveyor, usually made of carbon steel or stainless steel, providing a foundation for the installation and fixation of other components so that they can work stably.

Working principle of heavy duty belt conveyor

It is mainly composed of two end rollers and a closed conveyor belt tightly sleeved thereon. The roller that drives the conveyor belt to rotate is called the drive roller (transmission roller), and the other roller that only changes the direction of movement of the conveyor belt is called the redirection roller. The drive roller is driven by the motor through the reducer, and the conveyor belt is dragged by the friction between the drive roller and the conveyor belt. The drive roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed from the feeding end, falls on the rotating conveyor belt, and is transported to the discharge end by the friction of the conveyor belt.

Parameter table of conventional models of heavy duty belt conveyors

|

Item |

Parameter range or description |

|

Belt width (B) |

500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, 1600mm, 1800mm, 2000mm, 2200mm, 2400mm, etc. |

|

Conveying length |

Can be customized according to needs, usually 10m to 2000m or more |

|

Conveying capacity (t/h) |

50 to 5000 tons/hour, depending on the belt width, belt speed and material characteristics |

|

Conveyor belt speed |

0.8 to 4.0m/s (commonly 1.0, 1.2 5, 1.6, 2.0, 2.5, 3.15, 4.0m/s) |

|

Maximum inclination angle |

Usually ≤20°, with sidewall structure up to 30°~90° (vertical) |

|

Motor power |

7.5kW~500kW or more, configured according to conveying load and length |

|

Roller form |

Trough roller group, parallel roller group, self-aligning roller group, buffer roller, etc. |

|

Tensioning method |

Spiral tensioning, heavy hammer tensioning, hydraulic tensioning |

|

Conveyor belt type |

Ordinary rubber belt, tropical belt, acid and alkali resistant belt, wire rope core belt, anti-tear belt, etc. |

|

Frame material |

Carbon steel spray painting, carbon steel galvanized, stainless steel (optional according to working conditions) |

Main features of heavy duty belt conveyor

High load capacity: designed for conveying high-density and large-tonnage materials such as ore, coal, sand and gravel, with a single machine length of up to several thousand meters and a conveying capacity of up to several thousand tons per hour.

Strong conveying capacity: It can continuously or intermittently convey heavy materials, with large conveying volume and speed up to 1.3-2.0 m/s, suitable for long-distance conveying

Strong structure: It adopts high-strength steel frame, thick belt (such as ST series steel cord conveyor belt) and heavy duty roller, which is impact-resistant and wear-resistant.

Long-distance conveying: It can realize horizontal, inclined (generally ≤18°) or combined conveying, and some models are equipped with intermediate drive devices.

Flexibility and adaptability: It can be used alone or in a system of multiple units to meet the layout requirements of different production lines. It supports multi-point feeding, single-point or multi-point discharging, and some models (such as sealed belt conveyors) can reduce dust problems.

Technical specifications of heavy duty belt conveyors

|

Model |

Belt width (mm) |

Belt speed (m/s) |

Applicable conveying capacity (t/h) |

|

B800×2.0 |

800 |

2.0 |

300~400 |

|

B1000×2.5 |

1000 |

2.5 |

500~800 |

|

B1200×3.15 |

1200 |

3.15 |

800~1200 |

|

B1600×4.0 |

1600 |

4.0 |

2000~3500 |

|

B2000×4.0 |

2000 |

4.0 |

4000 and above |

Application of heavy duty belt conveyors

Heavy duty belt conveyors play a pivotal role in many industrial fields with their excellent carrying capacity and reliability. They are widely used in the mining industry to continuously transport minerals such as coal and iron ore from deep underground to the surface, or to transport huge amounts of stripping materials and ores in open-pit mines. At ports and docks, heavy duty belt conveyors are responsible for efficiently loading and unloading bulk goods such as grains, fertilizers, and ore, connecting ships and warehouses. Steel and cement plants also rely on them to transport high-temperature clinker, sintered ore, limestone, etc. In addition, large thermal power plants rely on them to transport coal from the yard to the boiler room to ensure fuel supply; while tunnel excavation projects use them to quickly transport large amounts of earth and stone out of the tunnel to ensure construction progress.

Solutions proven by our wide range of products

For many years, we have been committed to providing stable, efficient, and reliable heavy duty belt conveyor system solutions for multiple industries such as mining, power, metallurgy, cement, ports, and building materials. Through continuous technical optimization and on-site experience accumulation, our products have been practically verified and widely used in many projects across the country and even overseas.

|

Scenario |

Project requirements |

Solutions |

Application effects |

|

Open-pit mines-ultra-long-distance high-intensity transportation |

Transporting high-wear ore, single-line transportation distance exceeds 1.2 kilometers |

Adopting steel wire core conveyor belt, dual drive system, fully enclosed structure |

The equipment has been running continuously for more than 8,000 hours, and the failure rate is less than 0.3%. |

|

Cement plant - high temperature clinker conveying system |

Conveying cement clinker with a temperature of 200°C and a conveying distance of 250 meters. |

Equipped with high temperature resistant conveyor belt, automatic cleaner and anti-deviation device |

Ensure that the conveyor belt is free of debonding and slipping, and the continuous operation is stable and reliable. |

|

Port terminal - bulk coal loading line |

Annual loading and unloading capacity reaches 2 million tons, with high dust prevention and environmental protection requirements |

Adopt closed belt corridor + atomization dust suppression system + electric telescopic head |

Environmental protection acceptance is qualified once, and the operation efficiency is improved by 30%. |

|

Steel plant - slag and waste recycling and transportation |

Material has the characteristics of high temperature, high corrosion and high impact |

Thickened lining structure + buffer roller + corrosion-resistant rubber belt. |

The equipment has been running stably for three years, and the maintenance cost is 40% lower than that of traditional systems. |

If you need to select a model for a specific project, it is recommended to provide the following information:

Name and characteristics of the conveyed material (particle size, humidity, temperature, abrasiveness, etc.); conveying distance, inclination, conveying height

Hourly conveying volume or daily average output requirements; installation environment (indoor/outdoor, high temperature/dust/corrosion, etc.)