Infeed Belt Conveyor

Infeed belt conveyor is a continuous conveying equipment widely used in industrial production, mainly used to transport bulk materials (such as ore, coal, grain, fertilizer, etc.) from one place to another.

What is infeed belt conveyor?

Infeed belt conveyor is a mechanical equipment used for continuous material transportation. It is widely used in mines, power plants, ports, building materials, chemicals, grain and other industries. It is mainly used to transport bulk materials (such as ore, coal, sand, grain, etc.) or piece items from the feeding point to the designated location.

Belt width: ranges from 300 mm to 1200 mm

Conveyor belt length: customizable, usually up to 50 meters.

Capacity: 0.5 to 300 tons per hour

Belt speed: 0.5 to 5 m/s

Classification of infeed belt conveyor

|

Category |

picture |

Features |

Applicable scenarios |

|

Ordinary belt conveyor |

|

The most widely used, low cost, moderate conveying capacity |

Applicable to horizontal or inclined conveying of various bulk materials and block materials. |

|

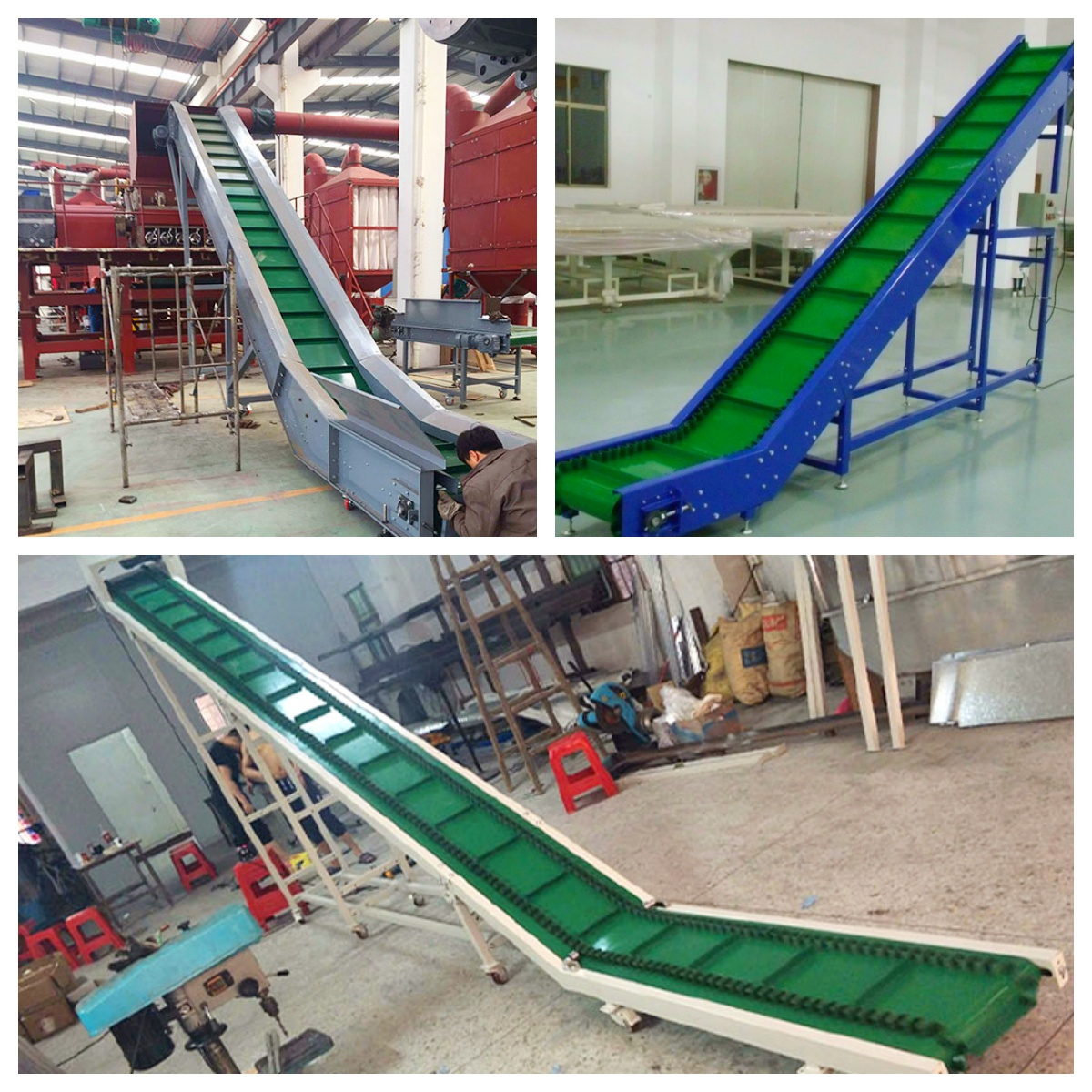

Pattern belt conveyor |

|

The conveyor belt surface has patterns to increase the friction between the material and the conveyor belt |

Applicable to large inclination angle or vertical conveying of bulk materials to prevent materials from sliding down. |

|

Sidewall belt conveyor |

|

The conveyor belt has corrugated sidewalls on both sides, which can convey larger inclination angles or even vertically convey bulk materials |

Applicable to large inclination angle or vertical conveying of bulk materials, with large conveying capacity. |

|

Tubular belt conveyor |

|

The conveyor belt is tubular, and the material is wrapped in it, which can realize closed conveying |

Suitable for occasions with high environmental protection requirements, easy to fly, toxic and harmful and can also realize spatial curve conveying. |

Video of infeed belt conveyor

What is the working principle of infeed belt conveyor?

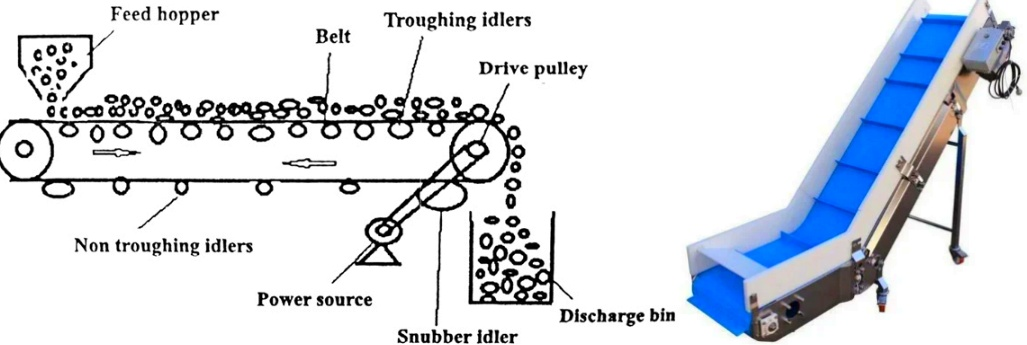

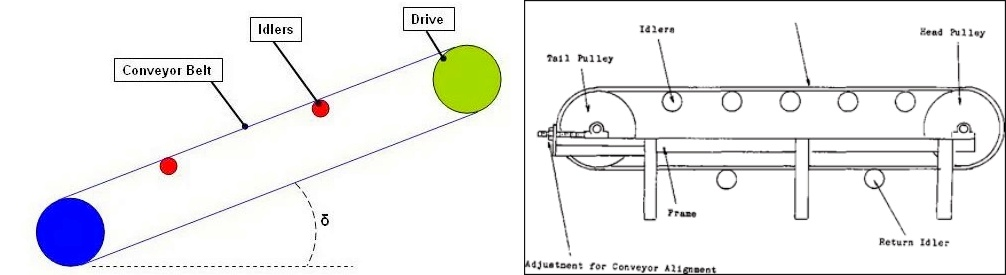

The motor drives the drive drum to rotate through the reducer, and uses the friction between the drum and the conveyor belt to drive the conveyor belt to circulate.

The material is evenly loaded onto the conveyor belt through the feeding device, and unloaded after the conveyor belt moves to the target position.

After the conveyor belt bypasses the head drum, it returns to the tail drum through the return roller to form a closed loop.

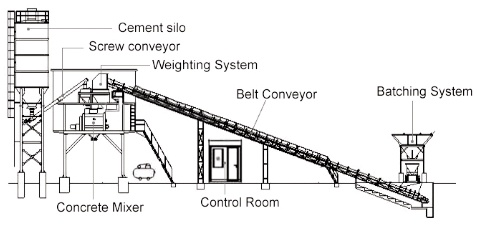

What is the structure of infeed belt conveyor?

Infeed belt conveyor is a mechanical equipment used to continuously transport materials to the next process link. It consists of the following main parts:

① Conveyor belt: a flexible belt-like component that carries and conveys materials, usually made of materials such as rubber, plastic or metal.

② Driving device: including motors, reducers, etc., to provide power for the operation of the conveyor belt.

③ Roller: The driving roller drives the conveyor belt to move through friction, and the redirecting roller changes the running direction of the conveyor belt. The tensioning roller can adjust the tension of the conveyor belt. The roller supports the conveyor belt to reduce the running resistance, and is divided into groove rollers, flat rollers, etc.

④ Frame: a metal structure that supports and fixes the various components of the conveyor.

⑤ Feeding device: a component that evenly transports materials to the conveyor belt, commonly including hoppers, feeders, etc.

⑥ Unloading device: a component that unloads materials from the conveyor belt, commonly including unloading rollers, scraper unloaders, etc.

Main features of infeed belt conveyor

Strong conveying capacity: Infeed belt conveyor can continuously transport a large amount of bulk materials or finished items, especially suitable for long-distance and large-volume material transportation needs. By choosing the right bandwidth, belt speed and conveyor belt type, a higher conveying efficiency can be achieved.

Strong adaptability of conveying lines: The belt conveyor can flexibly arrange the conveying lines according to the requirements of the terrain and process flow, and can convey horizontally, inclined or even vertically, and can also realize curved conveying. This makes it highly adaptable in complex production environments.

Wide range of applications: It can convey various types of materials, including powder, granular, block and various finished items. Whether it is bulk materials such as coal, ore, grain, or regular-shaped items such as cartons and bags, they can be conveyed by infeed belt conveyor.

Long conveying distance: Through reasonable design and configuration, long-distance material transportation can be achieved. In some industrial production scenarios, such as coal transportation in power plants, infeed belt conveyor can transport materials for several kilometers, reducing the loss and cost during material transportation.

Technical specifications of infeed belt conveyor

|

Parameter category |

Technical parameters |

Typical range/configuration |

|

Basic parameters |

Belt width (B) |

300mm, 500mm, 650mm, 800mm, 1000mm, 1200mm, 1400mm, 1600mm, 2000mm |

|

Belt speed (V) |

0.8~4.0m/s |

|

|

Conveying capacity (Q) |

10~5000t/h |

|

|

Conveying distance (L) |

Short distance: <50m; Medium and long distance: 50~500m; Long distance: 500m~several kilometers |

|

|

Conveying inclination (α) |

Flat belt: 0°~20°; Corrugated sidewall belt: 30°~90° |

|

|

Power configuration |

Motor power (P) |

1.5~500 kW |

|

Drive mode |

Single-point drive, dual-drive, multi-point drive |

|

|

Drum diameter |

Drive roller: 400~1500mm; redirection roller: 250~1000mm |

|

|

Conveyor belt material |

Rubber, PVC, nylon, steel wire rope core, silicone |

|

|

Belt thickness |

5~30mm |

Application of infeed belt conveyor

Infeed belt conveyor is widely used in all walks of life. It is mainly used to transport various bulk materials or unit goods from one location to another for the automatic transportation and processing of materials. The feed belt conveyor plays a vital role in modern industrial production and logistics transportation with its high efficiency, reliability and economy.

Material transportation: In mining, metallurgy, chemical industry, building materials, electricity, food processing and other industries, it is used to transport various raw materials, semi-finished products and finished products such as ore, coal, sand and gravel, cement, fertilizer, grain, sugar, salt, etc.

Production line integration: Connect equipment in different production links to realize automatic and continuous material transportation and improve production efficiency. For example, in the automobile manufacturing, home appliance production and other industries, it is used to transport parts and assemblies.

|

Application scenario |

Belt width (mm) |

Belt speed (m/s) |

Transport capacity (t/h) |

Power (kW) |

|

Mine coal transportation |

1200 |

2.5 |

1500 |

110 |

|

Port bulk cargo handling |

800 |

3.2 |

800 |

45 |

|

Grain processing line |

650 |

1.8 |

200 |

7.5 |

|

Cement plant clinker transportation |

1000 |

1.2 |

500 |

30 |

Selection suggestions for infeed belt conveyor

Conveying material characteristics: clarify the state of the material (powder, granular, block), particle size, humidity, temperature, whether it is sticky or corrosive, etc. For highly sticky or corrosive materials, special material belts (such as oil-resistant, acid-resistant, alkali-resistant, food-grade, etc.) should be selected.

Conveying capacity requirements: select appropriate bandwidth and belt speed according to the hourly conveying output (t/h). When the conveying capacity is large, it is preferred to use a wider belt (such as 800mm or more) and reasonably increase the belt speed.

Conveying distance and layout: Determine the conveying length and conveying angle based on the distance and height difference between the feeding point and the discharging point. It is recommended to use a sidewall belt conveyor when the inclination angle is greater than 15°.

Bandwidth selection: Common bandwidths are 500, 650, 800, 1000, 1200mm, etc., and can be selected based on the material particle size and conveying capacity with reference to national standards or experience values.