Z-Type High Volume Conveyor

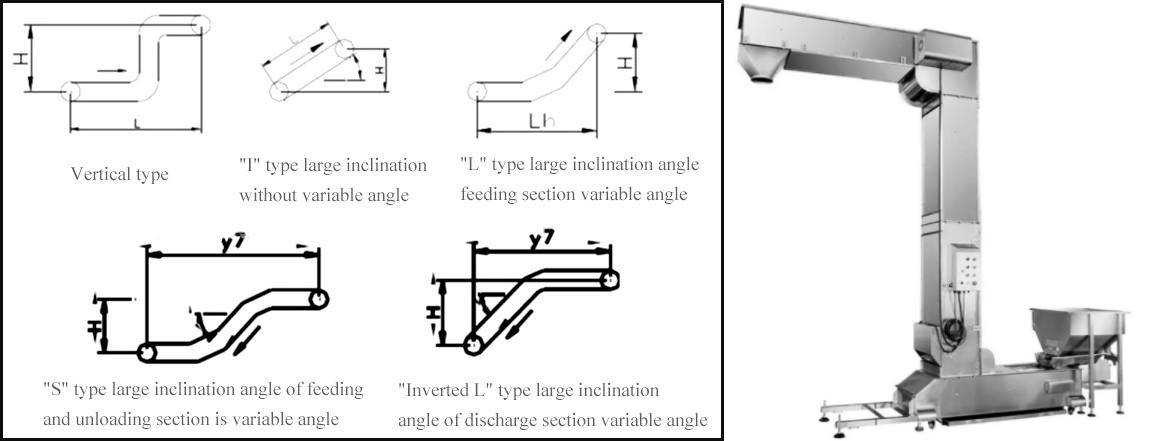

Z-Type high volume conveyor is a widely used equipment for vertically conveying bulk materials. Its conveying path is in the shape of "Z". This design enables it to convey a large amount of bulk materials or unit cargo in horizontal, inclined or even vertical directions. It is suitable for the smooth transfer of materials at different heights or between equipment.

Product Description

Z-Type High Volume Conveyor is a multi-stage continuous conveying equipment that combines vertical lifting and horizontal conveying. It is named because the overall layout is in the shape of "Z". Combined with the vertical and horizontal pipeline levels, it is particularly suitable for continuous pipelines that can realize large-scale conveying in limited spaces. Its core function is to realize efficient vertical lifting and horizontal transfer of materials in limited spaces. It is especially suitable for industrial scenes that require large throughput and limited space. It is often used for the conveying of particles, powders, and blocks. It is widely used in the transportation of mining, chemical, food, building materials and other industries.

Types of Z-Type High Volume Conveyors

|

Type |

Picture |

Structural features |

Applicable scenarios |

Advantages |

|

Z-type corrugated sidewall conveyor |

|

Corrugated sidewall belt plus transverse partition, Z-shaped path, bandwidth 500-1000mm, inclination 0-90° |

Chemical (plastic granules), building materials (cement), environmental protection (solid waste) |

1Suitable for bulk materials, large capacity (50-100t/h) |

|

Chain conveyor |

|

Stainless steel or carbon steel chain plate, chain plate width can be customized, suitable for heavy load |

Metallurgy (coke, slag), mining (ore), solid waste treatment |

Suitable for heavy load, high temperature materials |

|

Flexible chain conveyor |

|

Plastic or metal flexible chain, modular design, support complex paths |

Food (potato chips, biscuits), pharmaceuticals (tablets), logistics (light packages) |

Gentle conveying, low conveying capacity (<20t/h) |

|

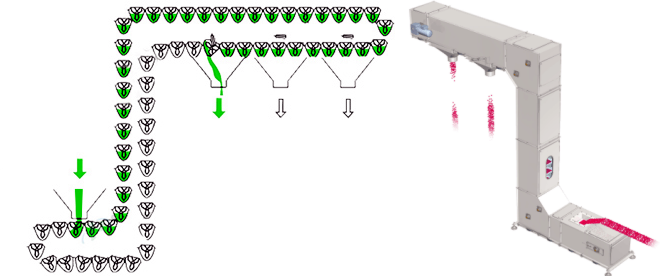

Z-type multi-point unloading conveyor |

|

Equipped with multiple unloading ports, hopper or belt design, unloading points can be customized |

Food (feed), chemical (multi-specification granules), warehousing (multi-bin distribution) |

Multi-point unloading, high degree of automation |

Video of Z-Type High Volume Conveyor

What is the working principle of Z-Type High Volume Conveyor?

①The material enters the horizontal conveying section from the feed port, and is driven forward by the friction of the conveyor belt.

②When the material reaches the inclined lifting section, the inclination angle of the conveyor belt causes the material to rise along the inclined direction under the combined action of gravity and the friction of the conveyor belt.

③The material passes through the horizontal discharge section and is transported to the designated location for unloading. During the entire conveying process, the drive device drives the conveyor belt through the motor and reducer to achieve continuous conveying of materials.

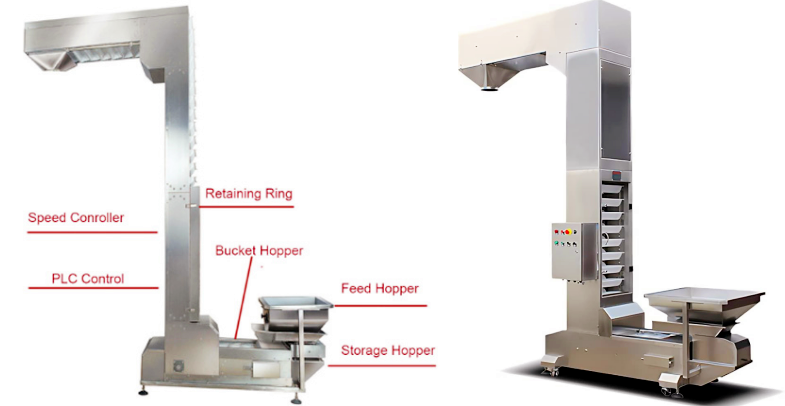

Structural composition of Z-type large-capacity conveyor

Z-type large-capacity conveyor is an efficient and compact material conveying equipment, which is widely used in material conveying scenarios that require vertical lifting or space constraints.

Conveyor belt/chain: High-strength rubber belt, steel cord belt or chain is used to carry materials and transmit power.

Drive device: The motor is matched with a reducer to drive the head wheel or sprocket to provide conveying power.

Steering device: Two 90° turns are achieved through rollers or guide wheels to form a Z-shaped path.

Rollers/guide rails: Support the conveyor belt to reduce running resistance.

Feed inlet and discharge outlet: located at the bottom and top (or reverse) of the Z-shaped structure respectively.

Tensioning device: adjust the tension of the conveyor belt to ensure smooth operation.

Main features of Z-shaped large-capacity conveyor

High space utilization: The Z-shaped structure can realize the combination of vertical lifting and horizontal transportation in a limited space, which is suitable for scenes with limited floor height or cross-floor transportation.

Large-capacity transportation: The wide conveyor belt (up to 2 meters) is combined with a high operating speed (0.5-2.5m/s), and the processing capacity of a single device can reach 500-2000m³/h.

Wide material adaptability: It can convey powdered (such as cement, flour), granular (such as ore, grain), and block (such as coal, ore) materials. Some models support high temperature (≤200℃) or corrosive materials.

Flexible conveying routes: The Z-shaped structure can be flexibly arranged according to the site layout to achieve horizontal to inclined and then horizontal, or horizontal to inclined and then vertical transportation.

Smooth conveying: With the conveyor belt as the conveying medium, the material is relatively stable during the conveying process, which reduces the damage and dust of the material, and is conducive to protecting the environment and improving the quality of the material.

Relevant parameters of Z-type large-capacity conveyor

|

Model |

HYZD-2L |

HYZD-5L |

|

Conveying volume |

0-6 cubic meters/hour |

0-12 cubic meters/hour |

|

Operating speed |

0.18 meters/second |

0.18 meters/second |

|

Single bucket capacity |

2.0 liters |

5.0 liters |

|

Lifting height |

customized |

customized |

|

Box size |

400*600 |

500*750 |

Technical specifications of Z-type large-capacity conveyor

|

Model |

TD160 |

TD250 |

TD315 |

TD400 |

||||||||||||

|

Bucket type |

Q |

h |

ZD |

Sd |

Q |

h |

zD |

Sd |

Q |

h |

ZD |

Sd |

Q |

h |

ZD |

Sd |

|

Conveying capacity (m3/h) |

5.4 |

9.6 |

16 |

16 |

12 |

22 |

23 |

35 |

|

30 |

25 |

40 |

24 |

46 |

66 |

41 |

|

Bucket width (mm) |

160 |

250 |

315 |

400 |

||||||||||||

|

Bucket capacity (L) |

0.5 |

0.9 |

|

1.9 |

1.3 |

2.2 |

3.0 |

4.6 |

|

3.6 |

3.8 |

5.8 |

3.1 |

|

5.9 |

9.4 |

|

Bucket distance (mm) |

280 |

350 |

360 |

450 |

|

500 |

480 |

560 |

||||||||

|

Belt width (mm) |

200 |

300 |

400 |

500 |

||||||||||||

|

Bucket speed (m/s) |

1.4 |

1.6 |

1.6 |

1.8 |

||||||||||||

|

Material quantity (mm) |

25 |

35 |

45 |

55 |

||||||||||||

|

Model |

TD500 |

TD630 |

TD160 |

TD250 |

TD350 |

TD450 |

||||||||||

|

Bucket type |

Q |

h |

ZD |

Sd |

h |

ZD |

Sd |

Q |

S |

Q |

S |

Q |

S |

Q |

S |

|

|

Conveying capacity (m3/h) |

38 |

70 |

|

92 |

85 |

14 |

2 |

89 |

8 |

4.7 |

18 |

22 |

42 |

25 |

50 |

|

|

Bucket width (mm) |

500 |

630 |

160 |

250 |

350 |

450 |

|

|||||||||

|

Bucket capacity (L) |

4.8 |

9 |

|

15 |

14 |

14.6 |

23.5 |

1.1 |

|

1.1 |

2.6 |

3.2 |

7 |

7.8 |

14.5 |

15 |

|

Bucket distance (mm) |

500 |

625 |

710 |

300 |

400 |

500 |

640 |

|||||||||

|

Belt width (mm) |

600 |

700 |

200 |

300 |

400 |

500 |

||||||||||

|

Bucket speed (m/s) |

1.8 |

2 |

1 |

1.25 |

1.25 |

1.25 |

||||||||||

|

Material quantity(mm) |

60 |

70 |

25 |

35 |

45 |

55 |

||||||||||

Application of Z-type large-capacity conveyor

With its unique structure and advantages, Z-Type high volume conveyor plays an important role in multiple industries and application scenarios, especially in the transportation of large-flow materials or unit goods that need to be lifted or the conveying direction changed.

Food industry: In flour mills, feed mills, etc., it is used to lift bulk materials such as wheat, corn, flour, bran, feed, etc. from low places to high-altitude equipment such as mixers, packaging machines, and silos. In food processing plants, it is used to transport granular raw materials such as white sugar, salt, and monosodium glutamate to subsequent mixing or packaging links.

Agriculture: In seed processing plants or fertilizer plants, it is used to lift bagged or bulk seeds and fertilizers to trucks, silos, or packaging lines. In farms or agricultural product processing plants, it is used to transport harvested grains, fruits, vegetables, etc., such as transporting grains from the field to the granary, or transporting vegetables to cleaning and grading equipment.

Chemical industry: Z-type large-capacity conveyors are used to transport raw materials such as plastic granules, powdered additives, pigments, etc. to mixers, reactors, or packaging equipment. Transport packaged chemical products (such as bagged resins, catalysts, etc.) from the production line to the warehouse or loading area.

Pharmaceutical industry: It is used to transport powdered or granular pharmaceutical raw materials to production links such as mixing and granulation. Due to the high hygiene requirements of the pharmaceutical industry, easy-to-clean materials and closed conveying are usually used. Boxed and bottled drugs are lifted from the packaging line to the cartoning machine or higher-level conveyor line for subsequent logistics processing.

Logistics warehousing: In logistics centers or warehouses, it is used to transport unit goods such as packages and cartons vertically or at a large angle between different floors, connecting different sorting areas or storage areas. As part of the automated sorting system, the package is lifted to a high conveyor line for sorting at different destinations.

Why choose Dahan Machinery's Z-type large-capacity conveyor?

Dahan Machinery has many years of experience in the field of conveying equipment, and has accumulated rich experience in design, manufacturing, installation and commissioning, and can provide mature and reliable Z-type large-capacity conveyor products.

1. Customization capability: Dahan Machinery has strong customized design and production capabilities, and can tailor the most suitable conveying system according to the customer's specific requirements such as plant layout, conveying material characteristics, conveying volume, and lifting height.

2. Stable and reliable product quality: The use of high-quality raw materials and advanced manufacturing processes can ensure that its Z-type conveyor operates stably and reliably, reduce failure rates, and reduce maintenance costs.

3. Higher conveying efficiency and capacity: Dahan Machinery's Z-type conveyor focuses on improving conveying efficiency and capacity in design, such as using appropriate conveyor belt speed, optimized hopper design, and powerful drive system.

4. Perfect after-sales service: Good after-sales service is an important consideration for equipment procurement. Dahan Machinery provides timely installation guidance, commissioning services, operation training, and equipment maintenance and repair services to ensure smooth production for customers.

The above content is based on the analysis of Dahan Machinery under general circumstances. When making actual choices, it is necessary to combine specific product parameters, customer evaluations, and other factors for comprehensive consideration.