Oil resistant conveyor belt

Oil resistant conveyor belts are used to convey oily materials or materials treated with oil. They are made of oil-resistant covering rubber, which can effectively suppress snaking, bending and reverse bending even when conveying oily materials (mineral oil, animal oil, vegetable oil).

Product Description

Oil resistant conveyor belt refers to a special conveyor belt that can run stably in an environment containing grease or oily substances, is not easily corroded, swelled, deformed, or cracked by grease, and can maintain its physical and mechanical properties and service life. Its main feature is that its cover rubber has excellent oil resistance and can resist the erosion of various industrial oils, edible oils, and animal and plant oils.

Oil resistant conveyor belt types

Oil-resistant conveyor belts are classified according to their structural forms, including flat oil-resistant conveyor belts, patterned oil-resistant conveyor belts and sidewall oil-resistant conveyor belts.

|

Types |

Flat oil resistant conveyor belts |

Patterned oil resistant conveyor belts |

Sidewall oil resistant conveyor belts |

|

Pictures |

|

|

|

|

Applicable materials |

Applicable to horizontal or inclined conveying of bulk, block or packaged materials |

Applicable to conveying at a large inclination angle |

Applicable to conveying bulk materials at a large inclination angle or vertically |

|

Surface features |

Flat surface |

Surface with various patterns (such as herringbone, V-shaped, diamond, etc.) |

With corrugated sidewalls and cross partitions |

Oil resistant conveyor video

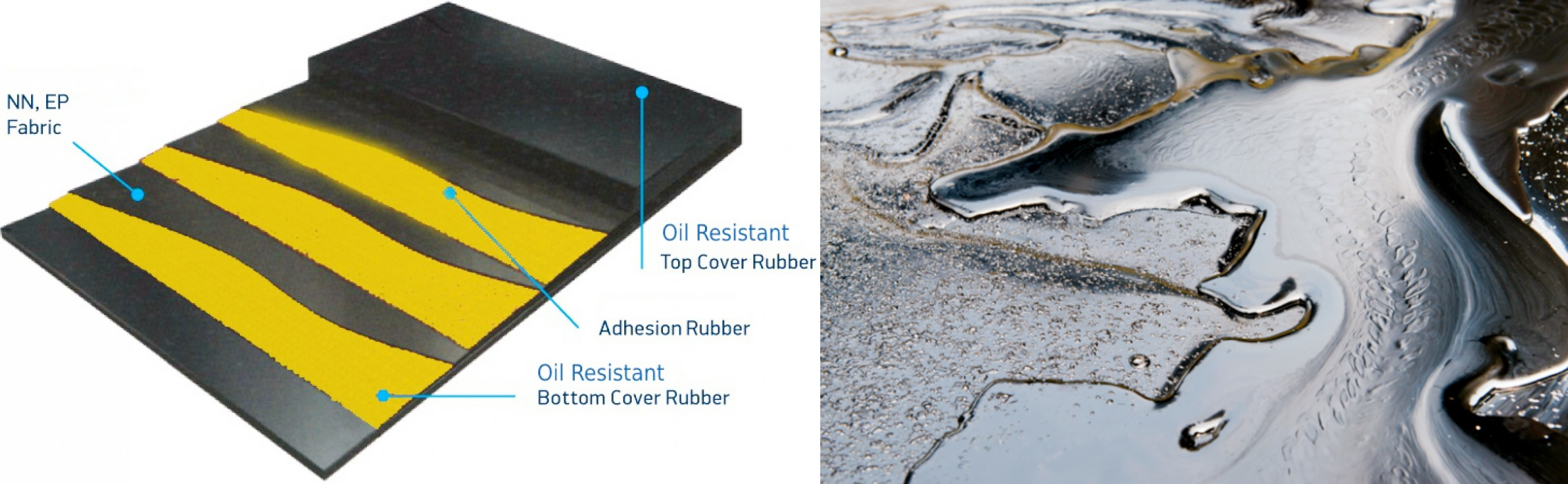

What is the structure of the oil resistant conveyor belt?

The structure of an oil resistant conveyor belt is designed to withstand exposure to oils, greases, and other hydrocarbons while maintaining durability and functionality. Below is a detailed breakdown of its typical layered structure: Top Cover (Oil-Resistant Layer)、 Carcass (Reinforcement Layer)、Bottom Cover、 Edge Seals (Optional)、Additional Features (Optional)

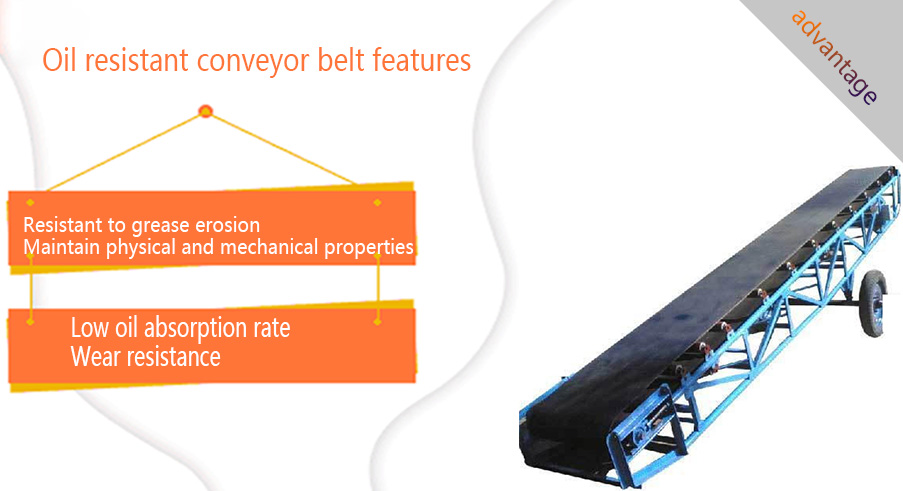

Oil resistant conveyor belt features

The core feature of oil resistant conveyor belts is their excellent oil resistance. According to different application requirements, they also have the following features:

Resistant to grease erosion: It can resist the erosion of various mineral oils, vegetable oils, animal oils, lubricating oils, fuel oils and other greases for a long time, and is not prone to swelling, softening, adhesion, cracking and other phenomena.

Maintain physical and mechanical properties: In an environment of contact with grease, the oil-resistant conveyor belt can maintain its original tensile strength, elongation, wear resistance and other physical and mechanical properties to ensure normal conveying operations.

Low oil absorption rate: The formula design of the covering rubber can minimize the absorption rate of grease and reduce the volume expansion and performance degradation caused by oil absorption.

Wear resistance: Considering the friction of the conveyed material, the covering rubber of the oil resistant conveyor belt also has wear resistance. In addition, flame retardancy, anti-aging, anti-static, acid and alkali resistance are also the characteristics of oil-resistant conveyor belts.

Technical specifications of oil resistant conveyor belts

|

Belt strength type (N/mm) |

Top Cover rubber thickness (mm) Backside |

Belt width (mm) |

|

160 |

3.0、1.5 |

300, 350, 400, 450 |

|

250 |

3.0、1.5 |

500,600 |

|

315 |

3.0、1.5 |

750,900 |

|

Product type |

Rubber type |

Application characteristics |

|

|

Oil-Resistant 210 black |

NBR |

nitrile |

This belt has resistance to aromatic solvents, halogenated hydrocarbon, ketone, and oils excluding esters. |

|

Oil-Resistant 220 black |

NBR +NR |

nitrile and natural |

This belt is used for applications that require a low level of oil resistance, and a low level of oil and cold resistance. It is suitable for conveying chips, frozen fishes, and grain. |

|

Oil-Resistant 300 |

PVC + NBR |

vinyl and nitrile |

This belt is used for applications that require a high level of oil resistance |

|

Oil-Resistant 310 black |

|

||

|

Oil-Resistant 330 white |

PVC + NBR |

vinyl and nitrile |

These are color-series order-made products of Oil-Resistant 300. |

|

Oil-Resistant 340 green |

|

||

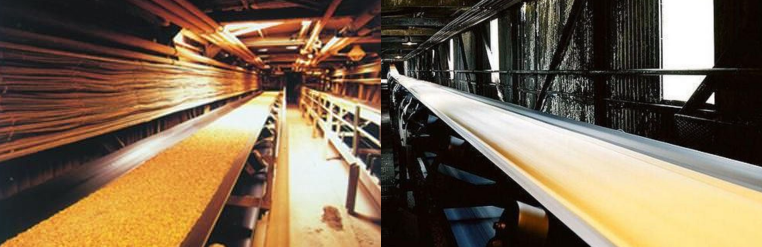

Application of oil resistant conveyor belt

Oil resistant conveyor belts are specially designed to transport oily or greasy materials without degrading the rubber or reducing performance. Oil resistant conveyor belts are specifically designed to transport materials containing oil or operate in environments where oil and chemical solvents are present. Their applications span multiple industries due to their excellent resistance to oil erosion, volume stability, and mechanical property retention.

|

Concrete plants |

recycling and mineral processing plants |

|

Waste sorting and composting machines |

metal processing industry |

|

Waste recycling |

wood industry, paper industry |

|

Sawmills |

manure and sewage sludge transportation |

|

Corn |

rapeseed and soil transportation |

Oil resistant conveyor belt price

The price of an oil resistant conveyor belt depends on several factors, including material, thickness, width, length, reinforcement type. Below is a general price range and key cost influencers:

|

Type |

Material |

Price Range |

Notes |

|

NBR (Nitrile Rubber) |

Oil-resistant rubber+fabric plies |

10–50(USD/m²) |

Most common, good balance of cost&performance |

|

PVC/PU Belt |

Polyvinyl Chloride/Polyurethane |

15–70(USD/m²) |

Light oil resistance, food-grade options cost more |

|

CR(Chloroprene Rubber) |

Chloroprene rubber+fabric reinforcement |

20–60(USD/m²) |

Better weather resistance than NBR |

|

Steel Cord Oil-Resistant Belt |

NBR+steel cords |

50–150+(USD/m²) |

Heavy-duty, high-tension applications |

|

PTFE(Teflon)Belt |

PTFE-coated fiberglass |

100–300+(USD/m²) |

Extreme oil&chemical resistance |

The above prices are only for reference, and the actual price needs to be determined according to the specific product requirements and supplier quotations. When purchasing oil resistant conveyor belts, it is recommended to obtain quotes from multiple suppliers, compare their product quality and prices, and choose the most suitable product for your needs.