Packaging conveyor belt

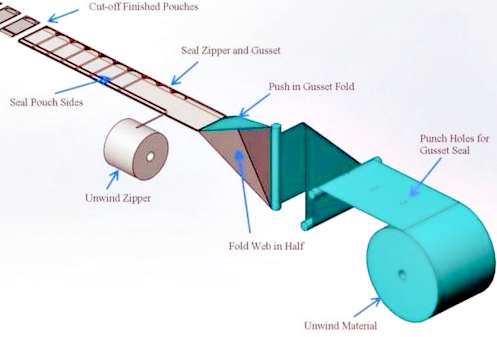

Packaging conveyor belt is a conveying equipment used for conveying materials or finished products in the packaging production line. It is mainly used to transport packaging materials (such as boxes, bagged products, bottles and cans, etc.) efficiently and stably, and ensure its continuity in the sorting, sealing, palletizing and other links. Its core function is to realize the automation and continuous conveying of materials or finished products, improve production efficiency and ensure product quality.

Product Introduction

Packaging conveyor belt is an industrial conveying equipment dedicated to the product packaging link. It is designed to efficiently, stably and safely transport the materials to be packaged or packaged from one station to another. It is mainly used to transport items from the production line and assembly line to the packaging and packaging process to meet specific packaging process requirements. It focuses on smooth transportation, accurate positioning, adaptation to different packaging forms, and meets the requirements of hygiene, light load and high-speed operation.

What are the three types of packaging conveyor belts?

Packaging conveyor belt is the core equipment in the packaging production line. There are many types of it. Based on the material, the packaging conveyor belt is divided into three types: PVC conveyor belt, PU conveyor belt and rubber conveyor belt.

PVC conveyor belt

Definition: PVC conveyor belt is a conveyor belt with PVC material as the surface covering layer, combined with polyester fiber or fabric core.

Applicability: Suitable for packaging lines with limited budget, light materials and medium hygiene requirements, such as fast-moving consumer goods and daily chemical packaging.

Size: The thickness is 1-5 mm, and the thin design is suitable for light materials; the width is tens of centimeters to 2 meters, which is flexible and customized, suitable for long-distance packaging lines.

PU conveyor belt

Definition: PU conveyor belt uses polyurethane as the surface material, usually combined with fabric or fiber core, which is wear-resistant and flexible.

Applicability: Suitable for food, medicine and electronic packaging, meeting high hygiene and precision requirements.

Size: The thickness is 0.8-4 mm, suitable for precision packaging; the width is tens of centimeters to 1.5 meters, suitable for small and medium-sized packaging lines; the length is a modular joint design, which is easy to adjust and extend.

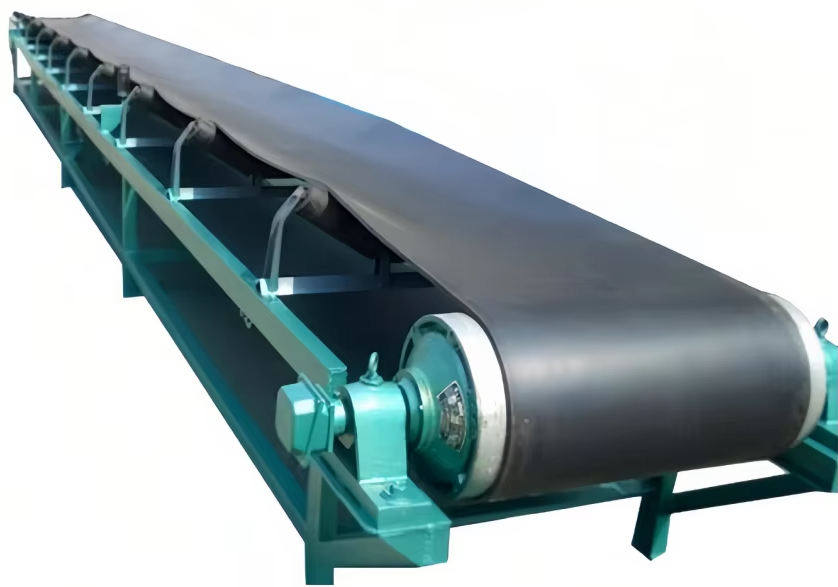

Rubber conveyor belt

Definition: The rubber conveyor belt uses natural or synthetic rubber as the surface material, with high wear resistance and strong load-bearing capacity.

Applicability: Suitable for packaging scenarios of heavy and rough materials, such as logistics and home appliance packaging.

Size: Thickness is 5-15 mm, and the thick design supports heavy loads; width is 1-3 meters, suitable for wide packaging lines and large production lines.

Comparison summary of packaging conveyor belts

|

Features |

PVC conveyor belt |

PU conveyor belt |

Rubber conveyor belt |

|

Mesh count |

Smooth or micro texture (low mesh count) |

Smooth or fine texture (low mesh count) |

Rough or raised (medium and high mesh count) |

|

Packaging characteristics |

Hygiene, low cost, high-speed conveying |

High hygiene, anti-static, precise conveying |

High load-bearing, wear-resistant, suitable for heavy packaging |

|

Advantages |

Low cost, easy to clean, high flexibility |

Strong hygiene, wear resistance, precision |

Strong load-bearing, wear resistance, adaptability to complex environments |

|

Limitations |

General wear resistance, low temperature resistance |

High cost, limited temperature resistance |

Poor hygiene, high energy consumption, high maintenance cost |

Video of packaging conveyor belt

What is the working principle of packaging conveyor belt?

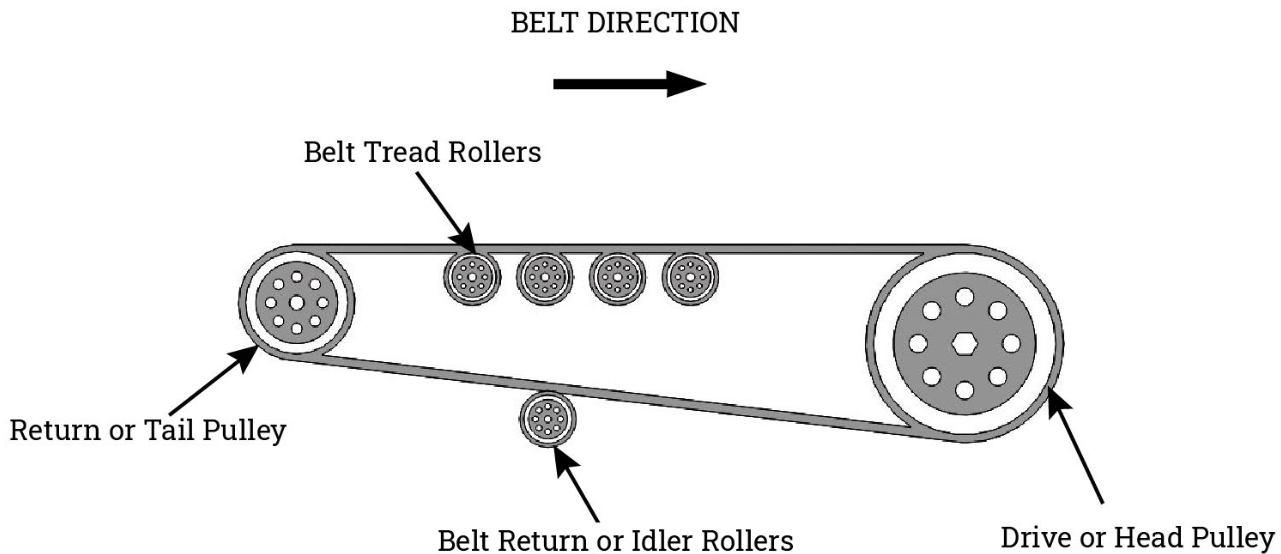

Packaging conveyor belt realizes the automatic and continuous conveying of products through the synergy of mechanical transmission, structural support, path guidance and intelligent control, and is an important part of the modern packaging production line.

Start-up phase: the control system issues a command, the motor starts, and the transmission device drives the conveyor belt to operate.

Conveying phase: the product is placed on the conveyor belt and moves along the set path driven by the transmission system. The support system ensures the stability of the conveyor belt, and the guidance system corrects the product position.

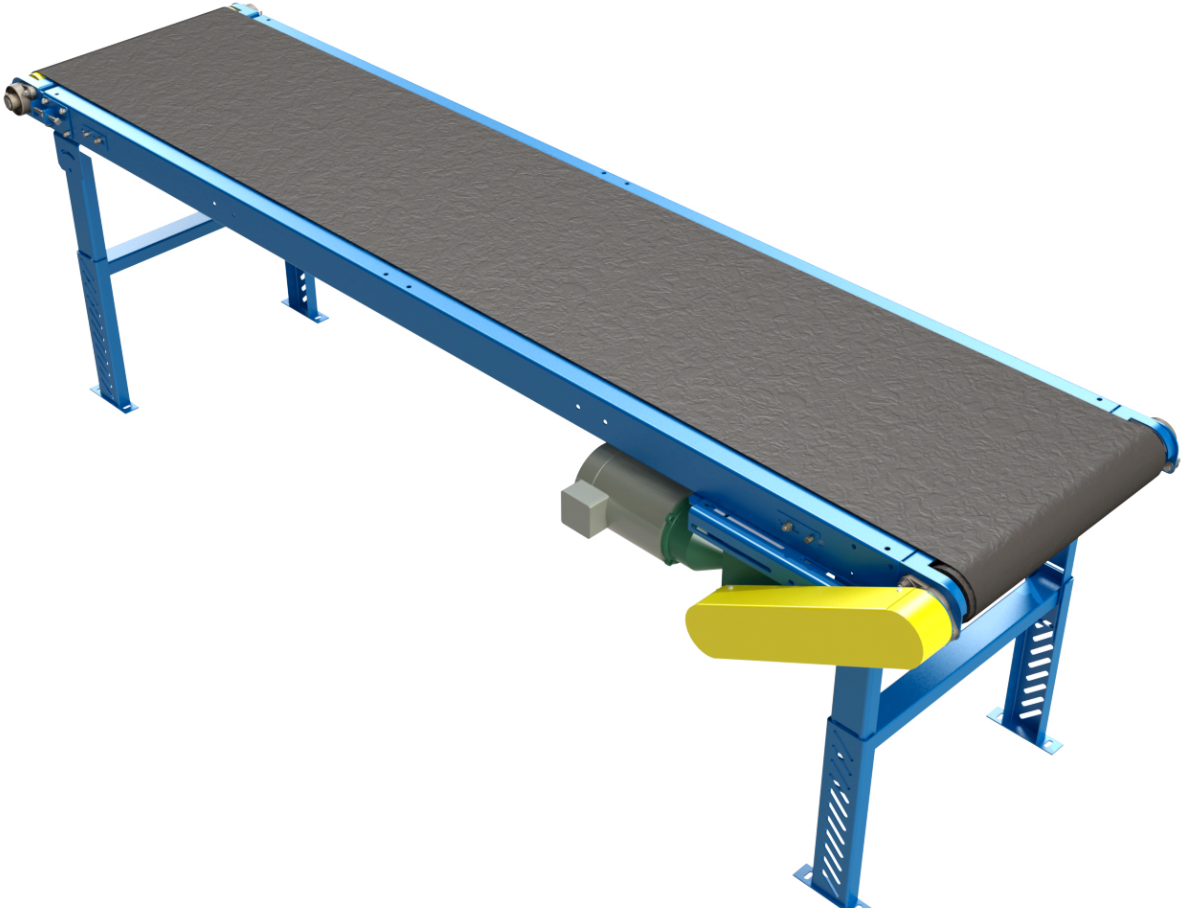

What are the components of a packaging conveyor belt?

Packaging conveyor belts are used to transport, position and handle materials during the packaging process. Its components work together to ensure efficient, precise and reliable conveying to meet the needs of industries such as food, pharmaceutical and logistics. Packaging conveyor belt systems are composed of conveyor belts, frames, drive systems, pulleys/rollers, support systems, tensioning/tracking systems, guides, controls, accessories and safety devices. Each component is designed to meet the technical specifications of the conveyor belt material (for example, PVC for light loads, PU for sanitary grades, and rubber for heavy loads) and packaging needs.

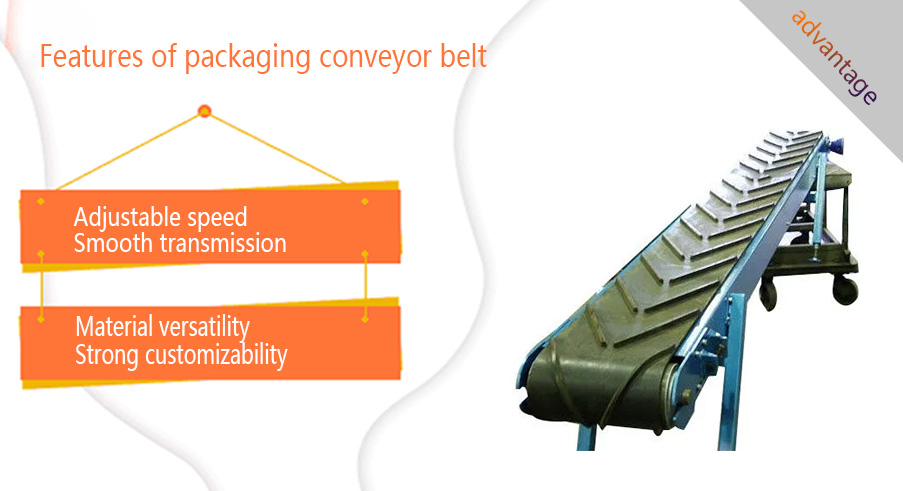

Features of packaging conveyor belt

Packaging conveyor belt is a key equipment in the modern packaging production line. Its design and function mainly serve the efficient, safe and automated transportation needs of the packaging process.

Adjustable speed: Usually equipped with a variable frequency drive (VFD) or a speed-adjustable motor, the conveyor belt running speed can be adjusted according to the packaging rhythm.

Smooth transmission: The packaging conveyor belt runs stably, which can ensure that the posture of the packaged items remains unchanged during the movement, preventing them from falling, tipping or slipping.

Material versatility: The belt surface of the conveyor belt can be PVC, PU, rubber, mesh, and selected according to the packaging type

Strong customizability: The length, width, height, material, and structure can be customized according to the needs of different packaging lines to adapt to various production environments.

The technical specifications of the packaging conveyor belt

|

Belt width(mm) |

Conveying length(m)\Power(kw) |

Conveying speed(m/s) |

Conveying amount(t/h) |

||

|

B400 |

≤10 |

12-15 |

5-30 |

1.25-2.0 |

30-60 |

|

|

3 |

3-4 |

4-7.5 |

|

|

|

B500 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

40-80 |

|

|

3 |

4-5.5 |

5.5-7.5 |

|

|

|

B650 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

80-120 |

|

|

4 |

7.5 |

7.5-11 |

|

|

|

B800 |

≤10 |

12-15 |

15-30 |

1.25-2.0 |

120-200 |

|

|

4 |

7.5 |

7.5-15 |

|

|

|

B1000 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

200-320 |

|

|

5.5 |

7.5-11 |

11-22 |

|

|

|

B1200 |

≤10 |

10-20 |

20-40 |

1.25-2.0 |

290-480 |

|

|

7.5 |

7.5-15 |

15-30 |

|

|

|

B1400 |

≤10 |

10-20 |

<20-40 |

1.25-2.0 |

400-680 |

|

|

11 |

15-22 |

22-45 |

|

600-1080 |

|

B1600 |

≤10 |

10-20 |

<20-50 |

1.25-2.0 |

|

|

|

15 |

22-30 |

30-75 |

|

|

|

B1800 |

≤10 |

10-20 |

<20-50 |

1.0-2.0 |

200-1500 |

|

|

18.5 |

30-45 |

45-110 |

|

|

|

B2000 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1000-2000 |

|

|

22 |

45-55 |

55-132 |

|

|

|

B2400 |

≤10 |

10-20 |

<20-40 |

1.0-2.0 |

1500-3000 |

|

|

30 |

55-75 |

75-185 |

|

|

What is a packaging conveyor belt used for?

Use Packaging Conveyor Belts to Transport Products Efficiently and Reliably Conveyor belts are used to transport products efficiently and reliably at all stages of the packaging process. They are essential in automotive. They play a key role in automating material handling. Automating material handling improves the speed, accuracy and productivity of manufacturing and packaging facilities.

Packaging conveyor belt manufacturer

Dahan Machinery is a company specializing in the manufacture of packaging conveyor belts. Its products are widely used in many industries such as food, agriculture, logistics, etc. Our packaging conveyor belts are made of a variety of materials to meet the conveying needs of different environments and materials. Customers can choose the appropriate material combination according to the characteristics of the conveyed materials (such as temperature, corrosiveness, cleanliness requirements, etc.).

If you have specific conveying needs or want to know more about Dahan Machinery's packaging conveyor belts, it is recommended to contact Dahan Machinery's sales team directly for professional advice and customized solutions.