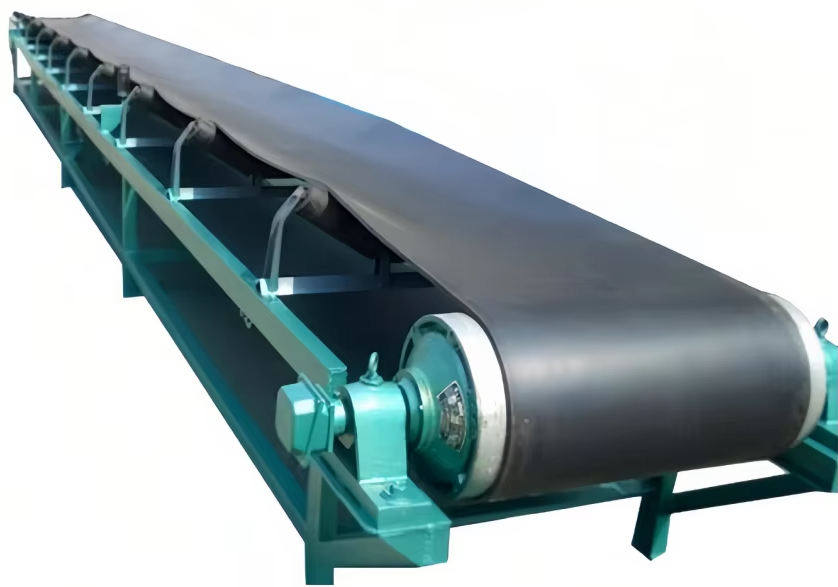

Recycling conveyor belt

Recycling conveyor belts are conveyor systems designed specifically for recycling facilities. These conveyors play a vital role in the efficient and continuous transport of a variety of recyclable materials, such as plastics, paper, cardboard, glass, metals and electronic waste, through the different stages of the recycling process.

Product Description

Recycling conveyor belts are key equipment used in the recycling industry to efficiently transport various waste materials. Their core function is to transport bulk, bagged or pieced materials from one place to another through continuous or intermittent conveying, which is convenient for subsequent sorting, handling or reprocessing. Depending on the application scenario and material characteristics, recycling conveyor belts have significant differences in structural design, material selection and functional configuration.

What is the core function of a recycling conveyor belt?

The core function of a recycling conveyor belt is to efficiently and continuously transport recyclable materials from one processing stage to another.

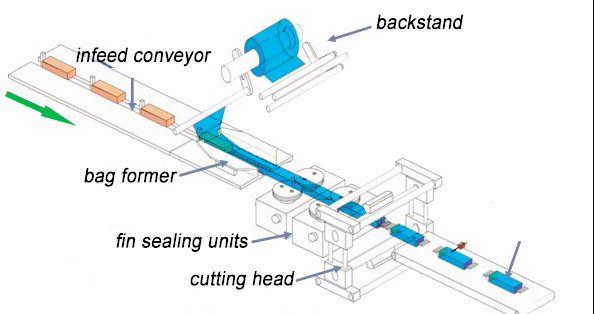

Automatic material transport: smoothly transport recyclables (such as paper, plastic, etc.) from one location to the next processing link.

Improve recycling efficiency: replace manual handling, greatly improve processing speed and efficiency, especially in garbage sorting or material recycling lines, and can operate continuously and uninterruptedly.

Material classification and coordination: with other equipment, realize automatic sorting of different materials.

Adapt to a variety of materials: can be designed to adapt to recyclables of different shapes, volumes and weights, such as soft plastics, broken glass, large scrap metal, etc.

Video of recycling conveyor belt

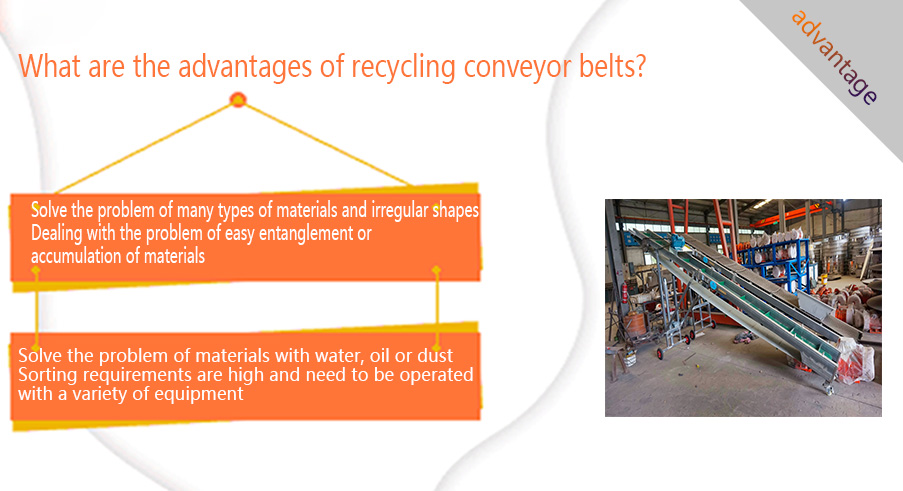

What are the advantages of recycling conveyor belts?

Materials will face many practical challenges during transportation, especially in recycling systems.

Solve the problem of many types of materials and irregular shapes

Recyclable materials have different shapes, and irregular shapes are prone to slipping or getting stuck. A conveyor belt with a baffle can be used to prevent the material from slipping. Designing a grooved belt or skirt lifting belt is more inclusive.

Dealing with the problem of easy entanglement or accumulation of materials

Plastic bags, thin ropes, and fiber materials are easy to entangle on the conveyor belt roller or drive shaft. The recycling conveyor belt adopts an anti-entanglement structure design and is equipped with a self-cleaning device to prevent accumulation.

Solve the problem of materials with water, oil or dust

Wet or greasy materials are easy to slip and contaminate the conveyor belt surface, affecting normal operation. Recycling conveyor belts use waterproof and non-slip materials such as PVC, rubber, and PU coated belts.

Sorting requirements are high and need to be operated with a variety of equipment

The recycling system usually involves multiple processes, such as etc., and has requirements for transmission speed, rhythm, and angle. The recycling conveyor belt can be designed as a multi-layer conveying structure to meet the needs of graded conveying.

Technical specifications of recycling conveyor belt

|

Parameter name |

Common value range/description |

Remarks |

|

Bandwidth |

400mm–2000mm |

Select according to material volume and conveying volume |

|

Conveying speed |

0.1–2.0m/s (adjustable frequency conversion) |

Usually needs to be set with sorting rhythm |

|

Conveying capacity |

1–100+ tons/hour |

Large recycling line can reach 200 tons/hour |

|

Conveyor belt material |

PVC, rubber, PU, chain plate, stainless steel mesh belt |

Select according to wear resistance, waterproof and corrosion resistance requirements |

|

Frame material |

Carbon steel spray paint/stainless steel/aluminum profile |

Stainless steel is suitable for corrosive and high humidity environments |

|

Working angle |

0°–30° |

Ramp-type structure is often used when lifting materials |

|

Drive mode |

Motor direct drive/reduction motor/sprocket chain drive |

Speed adjustment with inverter |

|

Load capacity |

50–2000kg/m |

Designed on demand, heavy-duty recycling can reach tons |

Application of recycling conveyor belts

Recycling conveyor belts are widely used in waste recycling, garbage sorting and resource recovery industries for efficient transportation and sorting of materials. For example:

Garbage sorting line: The conveyor belt transports mixed garbage to the sorting station to separate recyclables (such as plastic, metal, paper).

Automated recycling system: Through modular design, the transportation efficiency of the recycling plant is improved to adapt to complex production needs.

Application scenarios: Recycling of used household appliances, recycling of electronic products, recycling conveyor belts are used for material handling.

The Price of recycling conveyor belt

The price of recycling conveyor belts can vary widely based on several factors:

Model: Different types of belt conveyors have different conveying capacities and scope of application, which directly affects the manufacturing cost and price of the equipment.

Materials, such as rubber, nylon, etc., different materials have different wear resistance, tear resistance, and service life, which affects the price and specification.

Configuration: Whether the roller is coated, the number of rollers, the number of bars, and other configurations will also affect the price.

|

Model |

Belt width(mm) |

Length(m) |

Power(kw) |

Speed(m/s) |

Amount(t/h) |

Price(4/set) |

|

Horizontal recycling conveyor belt |

B500 |

3 |

4-7.5 |

1.25-2.0 |

40-80 |

$2120-10750 |

|

Inclined conveyor belt |

B650 |

3 |

7.5-11 |

1.25-2.0 |

80-120 |

$4100-24230 |

|

Vertical conveyor belt |

B800 |

4 |

7.5-15 |

1.25-2.0 |

120-200 |

$5500-36300 |

|

Fixed recycling conveyor belt |

B400 |

3 |

4-7.5 |

1.25-2.0 |

30-60 |

$2000-9430 |

|

Mobile conveyor belt |

B1000 |

5.5 |

7.5-22 |

1.25-2.0 |

200-320 |

$14800-249000 |

Customer case for recycled conveyor belts

Recycling conveyor belts are widely used in many industries. The following are different customer cases and specific applications:

|

|

|

|

|

School canteen tableware recycling conveyor belt |

Industrial production line recycling conveyor belt |

Conveyor belt for waste recycling |