bagged bread conveyor belt

The bagged bread conveyor belt is an automated conveying equipment designed for the food industry. It uses food-grade belts with adjustable width and speed. It can also be equipped with a screening device for diversion and grading.What is a bagged bread belt conveyor?

bagged bread belt conveyor is a conveying equipment designed for the food industry and is widely used for automated conveying after bread packaging. The equipment uses food-grade PU or PVC belts with a common width of 400mm800mm and an adjustable conveying speed of 530 meters/minute. The bagged bread belt conveyor can be equipped with a screening device for bread diversion and grading. The common screening mesh is 10~30 mesh, which can achieve horizontal, lifting, turning and other conveying methods.

Types of bagged bread belt conveyors

|

Type name |

Picture |

Feature description |

Applicable scenarios or advantages |

|

Horizontal conveyor |

|

The conveyor moves bread bags smoothly along the horizontal plane, with a simple structure and easy installation |

Horizontal conveying of materials in the bread production line, suitable for flat sites. |

|

Slope conveyor |

|

The conveyor belt is set at an angle, suitable for conveying bread bags from low to high or reverse |

Used for stacking, loading and other links, suitable for ramp transportation. |

|

Curve conveyor |

|

The conveyor belt is designed in a curved shape, which can change the conveying direction and adapt to space-constrained areas |

In narrow space environments, it is often used in small sites or production lines. |

Main functions of bagged bread belt conveyor

bagged bread belt conveyor is a device that conveys bread from one process to another through a continuous belt, and is commonly used in the following links:

① Product transmission: convey bagged bread from the packaging machine outlet to the boxing area or inspection area.

② Classification and diversion: sort products or classify them by specifications through multiple belt conveyor lines.

③ Lifting and descending conveyor: complete the vertical conveying of bread in a multi-layer workshop.

④ Buffer storage: temporarily store bread to avoid subsequent equipment blockage or overload.

Video of bagged bread belt conveyor

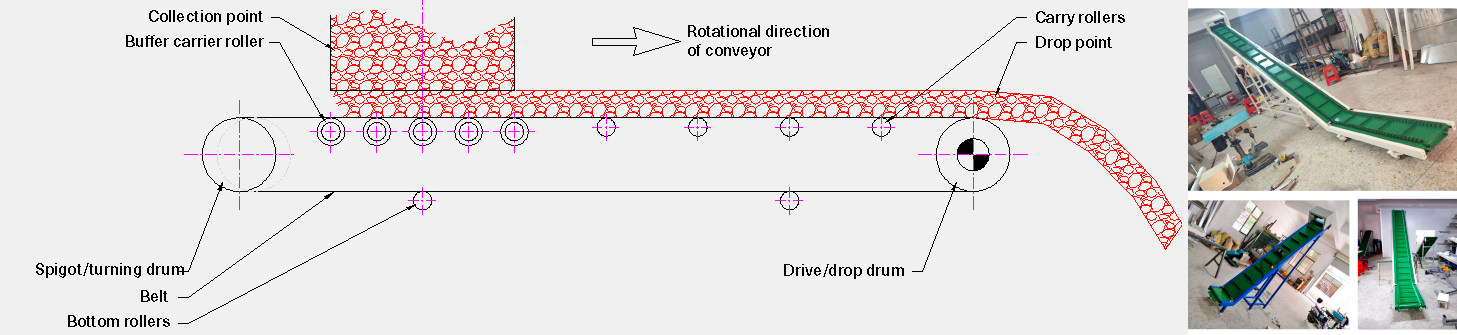

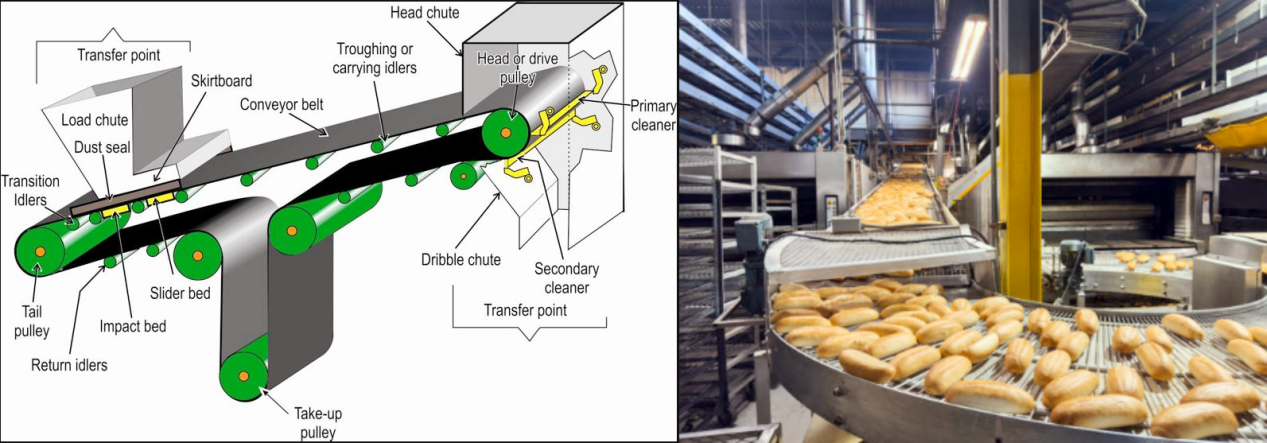

How bagged bread belt conveyor works

The working principle of bagged bread belt conveyor is relatively simple and efficient. Its core is to use a continuously circulating belt to drive bagged bread to move horizontally or inclined.

Power drive: The motor usually reduces the speed and increases the torque through a reducer, and then transmits the power to the active roller.

Movement of the belt: The active roller drives the conveyor belt wrapped around it to move through friction. The conveyor belt is usually a closed ring belt, which is tensioned between the active roller and the driven roller. The main function of the driven roller is to change the direction of movement of the belt and provide a certain tension to ensure the friction between the belt and the active roller.

Material carrying and movement: bagged of bread are placed on the moving conveyor belt. Due to the continuous movement of the belt, the bread will move from one position to another with the belt.

Tensioning device: In order to ensure that there is enough friction between the belt and the roller and prevent the belt from slipping, the conveyor is usually equipped with a tensioning device.

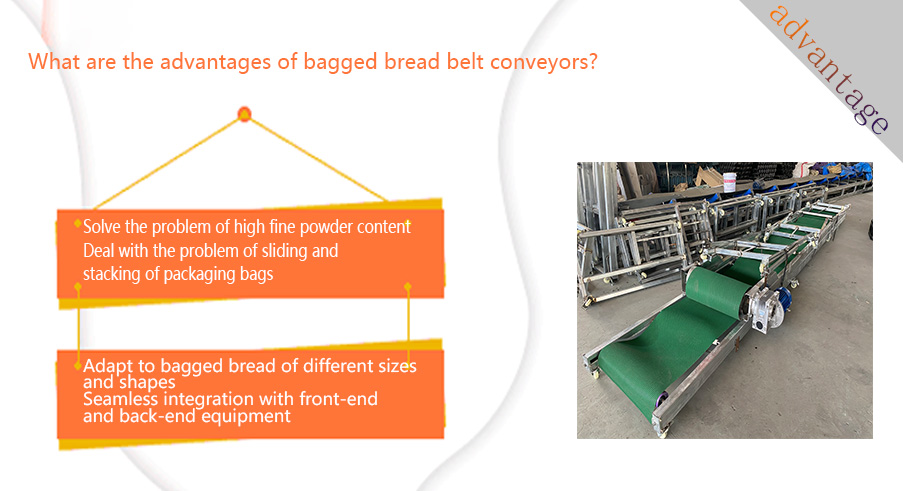

What are the advantages of bagged bread belt conveyors?

① Solve the problem of easy deformation and breakage of bread: bagged of bread are soft in texture and are easily squeezed and impacted during transportation, resulting in deformation, and even damage to the packaging bagged, affecting the appearance and quality of the product. Choose a belt material with a small friction coefficient and good elasticity to reduce friction and pressure on the surface of the bread. Through the motor and control system, ensure that the conveyor belt runs smoothly and avoid the impact caused by sudden stop or sudden acceleration.

② Deal with the problem of sliding and stacking of packaging bags: Smooth packaging bags are easy to slide when tilted or conveyed at high speed, causing bread to accumulate in certain areas and even cause blockage. Choose a belt with a certain texture or special coating on the surface to increase the friction between the packaging bagged and prevent sliding. When conveying at an angle, baffles or lifting ribs can be added to the belt to fix the bread in a specific position.

③ Adapt to bagged bread of different sizes and shapes: Different bread production lines have different process flows and plant layouts, and have different requirements for the form and function of the conveyor. The packaging size and shape of different brands or types of bread may vary. The bagged bread belt conveyor is flexible and can adapt to bagged bread of different specifications.

④ Seamless integration with front-end and back-end equipment: Modern bread production lines pursue high efficiency and continuity. The reliability and stability of conveying equipment are crucial. Any failure may cause the entire production line to stagnate. The bagged bread belt conveyor is usually part of an automated production line, seamlessly connected with the cooling line and packaging machine at the front end, and the inkjet printer, cartoning machine and other equipment at the back end to realize the flow of materials.

Parameters of bagged bread belt conveyor

|

Parameter name |

Description/common value range |

Remarks |

|

Conveyor belt width |

300mm ~ 800mm |

Customized according to bread size and arrangement |

|

Conveyor belt material |

PU, PVC (food grade) |

Comply with food contact standards, wear-resistant and easy to clean |

|

Conveying length |

1m ~ 20m customizable |

Customized according to workshop layout |

|

Conveying height |

Adjustable, or fixed height (usually 0.6m ~ 1m) |

Lifting feet can be added to adapt to equipment docking |

|

Conveying speed |

5 ~ 30 m/min (adjustable) |

Usually controlled by inverter or PLC |

|

Drive mode |

Motor drive (with reducer) |

Common configuration SEW, ABB, TECO and other brand motors |

|

Speed regulation mode |

Variable frequency speed regulation/constant speed |

Precisely match the production rhythm |

|

Frame material |

Stainless steel 304/aluminum alloy |

Food factories often choose stainless steel, anti-corrosion and resistant to cleaning |

|

Conveying mode |

Horizontal/lifting/turning |

Can be used in combination to adapt to complex production lines |

|

Carrying capacity |

Usually ≤30kg/m² |

Bread is light and the load requirement is not high |

Application of bagged bread belt conveyor

Bread conveying on the production line: In the initial stage of bread making, the mixed dough is conveyed from the mixing equipment to the forming equipment. After the bread embryo is formed, it needs to be conveyed to the proofing box and oven for proofing and baking. The bagged bread belt conveyor can accurately deliver the bread embryo to the designated position, and can also convey the freshly baked bread to the cooling area. During the conveying process, the bread is fully in contact with the air to achieve natural cooling.

Bread conveying in the packaging process: The cooled bread is conveyed to the packaging area by a belt conveyor, and the workers put the bread into the packaging bagged one by one beside the conveyor. The speed of the conveyor can be adjusted according to the operating speed of the packaging workers. The bagged bread belt conveyor can be used in conjunction with the weight detection equipment to convey the bagged bread to the weight detection scale for weighing.

Bread transportation in warehousing logistics: Packaged bagged bread needs to be transported to the warehouse for storage. The bagged bread belt conveyor can transport the bread directly from the packaging workshop to the designated location of the warehouse, which is convenient for workers to stack and stack. When the bagged bread needs to be shipped, the bread can also be transported from the warehouse to the shipping area, and the bread of different orders can be transported to the corresponding shipping port.

In short, the bagged bread conveyor belt is an important equipment to improve bread production efficiency, reduce labor costs, and ensure food safety. If you need more specific product recommendations or supplier contact information, please provide your budget, production line scale or whether you need a customized design, I can help you further screen!